- Aerosols Definition

- Aerosols ADVANTAGES/ DISADVANTAGES

- Types of Aerosols

- COMPONENTS OF AERSOLS

- CONTAINER

Definition :- Aerosols is defined as a system that depends on the power of a compressed or liquefied gas to expel the medicament which inside container.

Aerosols are pressurized dosage forms containing one or more medicament inside container and when valve is open its release its medicament.

ADVANTAGES:-

1. Avoid first pass metabolism.

2. Deliver uniform dosage form.

3. Targeted drug delivery system.

4. Due to presence of propellant its produce cooling effect in site of action.

5. It is used for medicament that are sensitive for oxygen, moisture, light or heat sensitive drug.

6. It is easy to use.

DISADVANTAGES :-

1. It is difficult to prepare aerosols dosage form of insoluble drug.

2. If long term used of propellant it is produced toxic effect.

3. It is expensive dosage form.

4. Some time its contaminate drugs by its trace metal that presence in container

Types of aerosols :-

1. Space spray :- this types of aerosols producing dispersion of particles which remain in the air for prolonged periods. The particles of spray are usually less then 50 µm in size.

2. Surface coating spray :- such aerosols used for producing a film on the surface treated this type of aerosols is relatively coarse. The particles range in size from 50 to 200 µm.

3. Foams :- They are formed when expansion of propellant within an emulsion results in production of small bubbles.

COMPONENTS OF AERSOLS :-

• CONTAINER

• VALVE

• ACTUATOR

• PROPELLANT

• MEDICAMENT

PROPELLANT :-

• It is responsible for developing proper pressure inside the container.

• When the valve is open they are relase proper medicament.

• It is regarded as the heart of aerosol package.

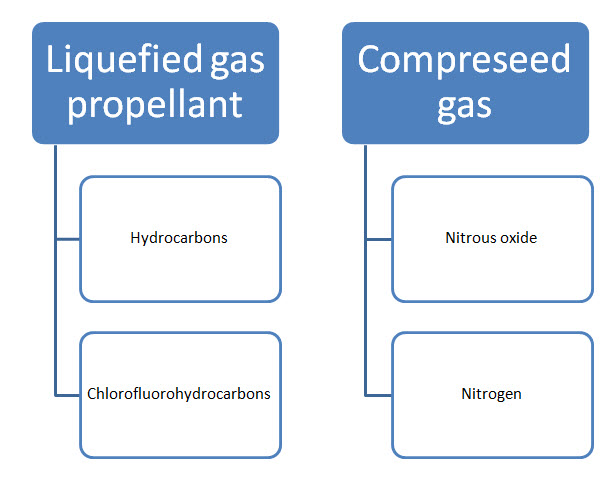

Classification of propellant :-

A. Liquefied gas propellant :- are exits as liquids under pressure but when valve is opened they convert into gas. It is divided into two sub types

1. Chlorofluorohydrocarbon :- It is mainly used for oral and inhalation preparation. Examples are trichloromonofluoromethan (Propellant 11), dichlorodifluoromethane (propellant 12) , dichlorotetrafluoromethane (propellant 114).

ADVANTAGE :-

• Chemical inertness

• Lack of toxicity

• Non flammability

• Lack of explosiveness

DIS ADVANTAGES :-

• High cost

• It depletes the ozon layer.

2.Hydrocarbons :- It can be used for water aerosols and topical use. Example propane (propellant A-108), Butane (propellant A-17).

ADVANTAGES :-

• Inexpensive

• Excellent solvent

• It does not cause ozone layer depletion.

DIS ADVANTAGES :-

• INFLAMMABLE

• UNKNOWN TOXICITY MAY BE PRODUCED

B. COMPRESSED GAS :-

Propellants can occupy the head space above the liquid. Example is carbon dioxide , nitrous oxide, and nitrogen.

When two propellants are mixture is vapour pressure is determined by Daltons law.

When propellants and other components are mix together its vapour pressure is determined by Raoult’s law.

1. CONTAINER :-

2. Aerosol container are generally made up of glass, metal, and plastic.

3. Aersols container withstand with high pressure as high as 140-180 psig at 130 F.

4. It is classified into three types 1. Glass container 2. Plastic container 3. Metal container

1) Glass container :- this type of container are used when low pressure and low amount of propellant are used. In this type of container no corrosion problem are seen. This type of container are used in topical & MDIs aerosols. It is also sub divided into two types 1. Coated 2. Uncoated

2) Plastic container :- It is highly permeable to vapour so may be chance of oxidative degradation in formulation.

3) Metal container :- This type of container are subdivided into three types

1. Tin plated steel 2. Stainless steel 3. Aluminium steel

1.Tin plated steel :-

• Tin are coated by electrolytic process.

• Three pieces of sheet

• Joined by soldering.

• Use of vinyl or epoxy coating to prevent of reaction due to soldering.

• Use for topical aerosols

2. Stainless steel

• No coating required

• Highly inactive

• Vinyl resions are not used in inside coating because of heat sterilized so epoxy is widely used.

• It is very costly it is only its dis advantage.

• It is used for mainly inhalation aerosols.

3. Aluminium

• It is very light weight.

• The combination of ethanol and propellant 11 in an aluminium container produces hydrogen, acetyl chloride , aluminium chloride, propellant 21 and other corrosive products.

• It is used both types of aerosols MDIs & topical aerosols.