About Authors:

About Authors:

Alpesh J.Shiroya*, K.K.Vaghasiya, N.J.ghantala

Bhagwan Mahavir College Of Biotechnology ,

Surat

*alpeshshiroya45@yahoo.in

Abstract

Clean technology has become an important concern for every industry. Especially in textile dyeing factories, there is much use of water, energy, dyeing colours and chemicals. This can cause significant water and air pollution problems. The wastewater wear a lot of colour and having toxic odour, COD and BOD. wastewater contains the following reactive dyes: turquoise DG, black DN, red DB-8 and orange OGR. It has been shown that the efficiency of dye removal depends on the type of dye, coagulant dosage, and the sample pH.The performance of COD and colour removal in the single-stage ozonation- biological treatment was also compared with the multi-stage ozonation-biological treatment processes. Ozonation transforms the functional groups in azo dye to produce more biodegradable by products, which is easily removed by biological treatment. semiconductor photocatalysis process could be an appropriate tool for the treatment for textile dyeing and printing wastewater. Activated sludge treatment and the coagulation-flocculation method with ≥80% removal efficiency of waste water. Using the electrocoagulation process possible the reuse of dye wastewater by removing the colours. sequential batch reactor (SBR) technology as an alternative method for treating industrial effluents.In the present work we review existing processes as well as promising new technologies for texttile waste water decolorisation.

[adsense:336x280:8701650588]

Reference Id: PHARMATUTOR-ART-1368

[ I ] INTRODUCTION

Water is life but now a-days due to the advancement in industrialization, it is spoiling a lot. Many contaminants present in wastewater, such as acids, bases, toxic organic and inorganic dissolved solids, and colors. Among them, colors are considered the most undesirable and are mainly caused by dyes [1]. Presence of colour and its causative compounds has always been undesirable in water used for either industrial or domestic needs. Different colouring agents like dyes, inorganic pigments, tannins, lignins etch usually impart colour. Amongst complex industrial wastewater with various types of colouring agents, dye wastes are predominant [2]. This wastewater not only toxic to the biological world, but it also has a dark colour, which blocks sun light. By these reasons, it causes many problems to the ecosystem [3]. The number of dyes presently used in textile industry is about 10,000. Among these dyes, azo dyes constitute the largest and the most important class of commercial dyes. Azo dyes are widely used in textile, plastic, leather, and paper industries as additives [4]. The removal of azo dyes in aquatic environment is important because many azo dyes are toxic to aquatic organisms [5].

There are some methods used for the treatment of dye-containing wastewater [6]. Coagulation is effective for treatment of insoluble dyestuff wastewater but not so effective for soluble dyestuff wastewater [7, 8]. The adsorption method has difficulties in the treatment of insoluble dyestuff wastewater and it is very difficult to find the desorption process [8,9]. The chemical method is to oxidize organic materials by oxidizing agents, such as ozone, H2O2, UV light or combination of such oxidants that is known as Advanced Oxidation Processes (AOPs). Most factories use this method to reduce COD and colour. But, it cannot satisfy the environmental discharge standard by itself alone and the cost is relatively high. The combination of ozonation and biological treatment seems to be promising unit processes to remove residual colour, COD and BOD of wastewater containing dye. The reaction between the oxidizing agent with dye in an aqueous environment lead to the decrease in aromaticity and molecular weight which eventually result in an increase in biodegradability and colour removal of dye. The biodegradable compound produced during ozonation would be removed by the following biological treatment. Therefore, the improvement of biodegradability is considered to be essential factor that determines the performance of ozonation –biological treatment process.

[adsense:468x15:2204050025]

Dye: Technologies for Colour Removal

Over the last few decades, society has become increasingly sensitive towards the protection of the environment. Due to this problem, mankind nowadays has concern about the potential adverse effects to the chemical industry on the environment, although the response in some parts of the world has been much faster and more intense than in others. The colour manufacturing industry represents a relatively small part of the overall chemical industry. Dyes and pigments are highly visible material. Thus even minor release into the environment may cause the appearance of colour, for example in open waters, which attracts the critical attention of public and local authorities.

Dyes are widely used in the Textile, rubber product, paper, printing, color photography, Pharmaceuticals, Cosmetics and Many other industries [10]. Dyes usually have a synthetic origin and complex aromatic molecular structures which make them more stable and more difficult to biodegrade [11]. Dyes tinctorial value is high: less than 1 ppm of the dye produces obvious coloration [12]. Due to their chemical structure, dyes are resistant to fading on exposure to light, water, and many chemicals [13]. Due to their complex struc-ture and synthetic origin, many dyes are difficult to be decolorized and decomposed biologically. There are many structure varieties such as acidic, basic, disperse, azo, diazo, anthroquinone based, and metal complex dyes.

[ II ] TECHNOLOGIES FOR COLOR REMOVAL

There are more than 100,000 commercially available dye exist and more than 7x105 tonnes per year are produced annually [14,15]. Wastewater containing dyes is very difficult to treat, since the dyes are recalcitrant organic molecules, resistant to aerobic digestion, and are stable to light. A synthetic dye in wastewater cannot be efficiently decolorized by traditional methods. This is because of the high cost and disposal problems for treating dye wastewater at large scale in the textile and paper industries [16]. The technologies for colour removal can be divided into three categories: biological, chemical and physical [15]. All of them have advantages and drawbacks.

A. Biological methods

Biological treatment is the often the most economical alternatives when compared with other physical and chemical processes. Biodegradation methods such as fungal decolourization, microbial degradation, adsorption by (living or dead) microbial biomass and bioremediation systems are commonly applied to the treatment of industrial effluents because many microorganisms such as bacteria, yeasts, alges and fungi are able to accumulate and degrade different pollutants [15,17]. However, their application is often restricted because of technical constraint. According to Bhattacharyya and Sharma, (2003), [18] biological treatment requires a large land area and is constrained by sensitivity toward diurnal variation as well as toxicity of some chemicals, and less flexibility in design and operation. Further, biological treatment is incapable of obtaining satisfactory colour elimination with current conventional biodegradation processes [19].

There are many types of biological treatment methods. Among them include trickling filters, activated sludge process, anaerobic process, oxidation ponding etc. To date the commonest treatment of textile wastewater has been based on mainly on aerobic biological process, consisting mainly conventional and extended activated sludge system. The trickling filters simulate stream flow by spraying wastewater over a broken, medium such as stone or plastic. The medium serves as a base for biological growth, which attacks the organic matter of wastewater, and uses it as food.

In activated sludge process, the wastewater flows into a tank after primary settling. The microorganism in activated sludge is suspended in the wastewater as aggregates. The sludge and wastewater is kept in suspension by compressed air, which also supplies the oxygen, necessary for biological activities. The aerated waste is continuously withdrawn and settled and a portion of the sludge is returned to the influent.

Biological methods of removing pollutants from wastewater using natural process involving bacteria and other microorganism for oxidation of the organic waste. Biological methods are generally cheap and simple to apply and are currently used to remove organic and color from dyeing and textile wastewater. Most of existing process includes an initial step of activated sludge treatment to remove the organic matters, followed by oxidation, membrane, activated carbon etc.

Anaerobic and aerobic treatments have been used together or separately for the treatment of textile effluents. Hence aerobic treatment is not effective in colour removal from textile wastewater containing azo dyes. Conventional biological process are not effective for treating dyestuff wastewater because many commercial dyestuff are toxic to organism being used and result in the problems of sludge bulking, rising sludge and pin flock. Because of low biodegradability of many textiles chemicals and dyes, biological treatment is not always effective for textile industry wastewater .

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

Biodegradation - Anaerobic Treatment

Anaerobic reduction of azo dyes using microbial sludges can be an effective and economic treatment process for removing color from dyehouse effluents. Although this effectively alters the chromogen and destroys the observed color of the dye, many aromatic groups are not susceptible to anaerobic reduction. However, there is evidence that some azo dye metabolites may be fully stabilized in anaerobic environments [20,21].

Aerobic Treatment

Conventional activated sludge treatment of wastes is often an effective and highly economic system for reducing organic pollutants in wastewater. A fair amount of research has been conducted assessing the viability of using activated sludge to treat textile effluents [22,23,24]. However, aerobic treatment of azo dye wastes has proven ineffective in mostcases, but is often the typical method of treatment used today [25]. Because aerobic microbes cannot reduce azo linkages, their ability to destroy dye chromogens is less than anaerobic bacterium. However, aerobic sludges have been successfully used to stabilize dye metabolites [26].

The majority of previous research suggests that aerobic biodegradation of most azo dyes is not effective. While there are certainly exceptions to the case, it would appear that conventional activated sludge systems are not adequate for treating azo dye wastewaters. Evidence does show that the aerobic biodegradation of azo dye intermediates is possible and is perhaps an effective treatment process for stabilizing these compounds after anaerobic reduction.

Azoreductase is the key enzyme expressed in azodye-degrading bacteria that catalyses the reductive cleavage of the azo bond. Azoreductase activity has been identified in several species of bacteria recently; such as Caulobacter subvibrioides C7-D, Xenophilus azovorans KF46F, Pigmentiphaga kullae K24, Enterobacter agglomerans andEnterococcus faecalis.Efforts to isolate bacterial cultures capable ofdegrading azo dyes started in the 1970s withreports of Bacillus subtilis, thenAeromonas hydrophila followed byBacillus cereus. Numerous bacteriacapable of dye decolorization, either in purecultures or in consortia, have been reported.

B.Chemical methods

Chemical methods include coagulation or flocculation combined with flotation and filtration, precipitation-flocculation with Fe(II)/Ca(OH)2, electroflotation, electrokinetic coagulation, conventional oxidation methods by oxidizing agents (ozone), irradiation or electrochemical processes. These chemical techniques are often expensive, and although the dyes are removed, accumulation of concentrated sludge creates a disposal problem. There is also the possibility that a secondary pollution problem will arise because of excessive chemical use. Recently, other emerging techniques, known as advanced oxidation processes, which are based on the generation of very powerful oxidizing agents such as hydroxyl radicals, have been applied with success for the pollutant degradation. Although these methods are efficient for the treatment of waters contaminated with pollutants, they are very costly and commercially unattractive. The high electrical energy demand and the consumption of chemical reagents are common problems.

C. Physical methods

Different physical methods are also widely used, such as membrane – filtration processes (nanofiltration, reverse osmosis, electrodialysis) and adsorption techniques. The major disadvantages of the membrane processes is that they a limited lifetime before membrane fouling occurs and the cost of periodic replacement must thus be included in any analysis of their economic viability. In accordance with the very abundant literature data, liquid-phase adsorption is one of the most popular methods for the removal of pollutants from wastewater since proper design of the adsorption process will produce a high-quality treated effluent. This process provides an attractive alternative for the treatment of contaminated waters, especially if the sorbent is inexpensive and does not require an additional pre-treatment step before its application. Adsorption is a well known equilibrium separation process and an effective method for water decontamination applications [27]. Adsorption has been found to be superior to other techniques for water re-use in terms of initial cost, flexibility and simplicity of design, ease of operation and insensitivity to toxic pollutants. Decolourisation is a result of two mechanisms: adsorption and ion exchange [28], and is influenced by many physio-chemical factors, such as, dye/sorbent interaction, sorbent surface area, particle size, temperature, pH, and contact time [29]. Adsorption also does not result in the formation of harmful substance.

D. Enzymatic processes for colour removal

In an attempt to overcome some of the problems associated with whole biological systems, recent research has focused on the application of enzymes, purified to the necessary extent [30]. Indeed, the potential for using enzymatic systems for colour removal has been recognized for some time. The reasons for this interest are many : (1) the rate of introduction of recalcitrant pollutants into the environment is increasing, and it is becoming increasingly difficult to achieve an acceptable degree of removal of these pollutants using conventional chemical and biological processes; (2)there is need to develop alternative methods that are faster, cheaper, more reliable, and simple to implement; (3) there is growing recognition that enzymes can be used to target specific pollutants for treatment; (4)recent biotechnical advances make it possible to produse enzymes more cheaply and with characteristic that are in tune with targeted application; and (5) enzymatic processes are amneable to process control.

The key to the successful application of enzymes for wastewater decolourization is the selection of an appropriate cocktail [30].many authors have recognized the potential for enzymatic treatment systems. However, the development of these processes from an industrial perspective has lagged behind. The main reasons for this appears to be the cost of enzymes that have traditionally been very expensive to produce in the quantities that are requried at an industrial scale. Enzymes are expensive because of the cost of their isolation, purification and production. Apart from the costs, the effect of each of the operational parameters on the colour removal process must be investigated using real textile effluent. In any case, introduction novel fermentation technologies together with new host systems for enzyme overproduction means that some of the major barriers that have limited the applicability of enzyme technology can be overcome.

In a recent pilot-scale trial Soares and co-workers showed that a suitably selected enzymatic cocktail could be used to remove colour from real industrial process waters. In this trial, colour removal was measured at the three wavelengths specified by EU legislation, and followed over a 3 month period. This approach appears to be promising as the textiles tested after being processed with the recycled waters showed satisfactory properties in terms of colour difference and washing fastness. Nevertheless, these trials carried out at the textile company require further validation.

[III ]BACTERIAL DECOLORIZATION OF TEXTILE DYE- ORANGE 3R

The dye decolorizing isolates, Bacillus sp., Klebsiella sp. Salmonella sp. and Pseudomonas sp. were isolated from the textile effluent samples. Different parameters such as various carbon source, nitrogen source, temperature, pH and inoculum size were optimized for decolorization of Orange 3R by using bacterial isolates. Pseudomonas sp. and Bacillus sp. Showed maximum dye decolorization of 89% at the end of 144h under optimum condition. But the Bacillus sp. was found to be more efficient in dye decolorization.

In recent years a number of studies have focused on some microorganisms that are able to degrade and absorb dyes from wastewater. A wide variety of microorganisms are capable of decolorization of a wide range of dyes some of them are as

bacteria:Escherichia coli NO3, Pseudomonas luteola, Aeromonas hydrophila ;

fungi:Aspergillus niger, Phanerochaete chrysosporium, Aspergillus terricola , P. chrysosporium ;

yeasts:Saccharomyces cerevisiae, Candida tropicalis, C. lipolytica ;

algae:Spirogyra species , Chlorella vulgaris , C. sorokiniana , Lemna minuscula , Scenedesmus obliquus, C. pyrenoidosa and Closterium lunula.

[A] Removal of industrial dyes by Microbes

Colored dye wastewater presents a challenging task for biological treatment. At present, dyes are generally removed by the use of activated charcoal or ultracentrifugation. Dramatic dye color removal can be achieved by microbial means. For example, a 99% reduction in red dye was achieved by biological treatment in 48 hours. A wide range of microorganisms is able to remove dyes from water including the yeast and bacteria.

[B] Use of bacteria to degrade Malachite Green

It was found that the best bacterium for degradation of the Malachite Green dye is Ochrobacterium anthropi. This bacterium can be obtained from the sludge of the waste water treatment plant.

Malachite Green (MG) is a triphenyl methane dye, which is most widely used for coloring purpose, amongst all other dyes of its category [31]. MG has properties that make it difficult to remove from aqueous solutions. If the solution containing MG discharged into receiving streams it will affect the aquatic life and cause detrimental effects in liver, gill, kidney, intestine and gonads. In humans, it may cause irritation to the gastrointestinal tract upon ingestion. Contact of MG with skin causes irritation and redness and pain. Upon contact with eye will lead to permanent injury of human eyes and laboratory animals.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

[C] Use white rot fungi to decolourise dyes

White rot fungus can decolourize a number of dyes, particularly crystal violet dye which is often used to dye jeans [32]. This rot fungus requires a growth substrate and a fixed surface for efficient colour reduction.

[D] Biodegradation of Leather

Acid dye by Bacillus subtilis

The Bacillus subtilis was used to decolorize the Acidblue113. The bacterial culture exhibited 90% decolorization ability within 50 h. Maximum rate of decolorization was observed (90%) when starch & peptone was supplemented in the medium. Decolorization of Acidblue113 was monitored by TLC, which indicated that dye decolorization was due to its degradation into unidentified intermediates. The optimum dye decolorizing activity of the culture was observed at pH 7.0 and incubation temperature of 370C. Maximum, dye-decolorizing efficiency was observed at 200 mg/l concentration of Acidblue113. A plate assay was performed for the detection of decolorizing ability of bacteria. Clearing zone (decolorization) was formed surrounding the bacterial culture. Decolorization was confirmed by UV-VIS spectrophotometer. The initial dye solution showed high peak at the wavelength of 560nm. The decolorized dye showed disappearance of peak, which indicated that the decolorization is due to dye degradation. The dye decolorization was further confirmed by COD & BOD Analysis.

[IV] Nanocatalyst for dye removal from waste water

Factories across the world are dumping thousands of tonnes of untreated dyes into rivers and waterways every year. The majority of these dyes are toxic to the environment and may lead to mutations and cancers in animals. Particularly in textile industries where considerable amounts of water and chemicals are used during the dyeing process the wastewater contains about 20% of dye as well as organic matter, salts and other substances. Also since synthetic dyes are used to resist bleaching by UV-light and chemicals to improve the quality of the textiles, they are also persistent in the environment and some dyes can be biologically modified into carcinogenic compounds. For example azo dyes, a commonly used dye to color fabrics can cause cancer if released into the environment with wastewater.

Removal of color from dye wastewater

The release of untreated wastewater has high color, high chemical oxygen demand, low biodegradabilityand high variability, it poses a threat to the animal and human health, environment and the most serious problems are ground water and surface water pollution. Further, the discharge of colored effluents into water bodies affects the sunlight penetration which in turn decreases both the photosynthetic activity and dissolved oxygen levels. The removal of dyes from wastewater is one of the major environmental challenges.

Removal techniques

Wastewater containing dye is conventionally filtered using activated carbon. However, the carbon can only be used once and is then commonly disposed of in landfill sites. Biotechnological treatment methods called dye remediation can be used for the treatment of dyes using biological and physico-chemical techniques. Different techniques are adopted to treat dye wastewater including adsorption, catalytic oxidation, chemical oxidation, photocatalysis, electrochemical process, biodegradation and catalytic wet oxidation by adding catalysts and oxidants to improve the oxidation rate.

Catalytic wet oxidation

Catalytic wet oxidation process is usually carried out at high temperature and pressure, which restrict its wide application. More and more efforts have been focused on developing new processes to improve the efficiency of CWO, such as the preparation of new type heterogeneous catalysts with high catalytic activity. CeO2 or CeO2-based oxides materials by virtue of their large surface area exhibit greater catalytic activity in CWO.

Recovery

It is very hard to recover pure CeO2 or CeO2-based oxides powders from water when they are used in aqueous systems. Coating the particles onto other materials is the promising method to resolve this problem. Supports of silica and γ-Al2O3 have been used to prepare the CeO2-based catalysts, but, the supports, synthesized by chemical reactions have inherent defects such high cost, time consuming reaction and low surface area.

Natural nanostructural material

Attapulgite (ATP) is a crystalline hydrated magnesium aluminum silicate with reactive –OH groups on its surface with a structure of zeolite-like channels. Due to its regular structure and large specific surface area, ATP has been used as absorbent, catalyst and catalyst support. Zhao et al. prepared copper modified palygorskite/TiO2 photocatalyst by hydrolysis method, which exhibited much higher activity than that of the pure titanium dioxides in the degradation of methylene blue. In addition, it was reported that the redox couple (Ce3+/Ce4+) in contact with metal particles promoted the catalytic activity in ceria-based materials. It is effective way to enhance the catalytic reaction rate that modified the palygorskite clay with copper ions since addition of rare metal ions to CeO2-based catalytic systems.

Color Removal from Textile and other Industrial Wastewater using Ozone

Ozone has been used for successfully for removal of color from textile wastewater streams in plants around the world as well as in other industrial wastewater processes. In wastewater treatment, ozone is often used in conjunction with biological treatment systems such as activated sludge. Organic dyes are mostly refractory due to their large molecular size and they can be poorly removed by adsorption on activated sludge. In some cases ozone has been used before the biological process, but mainly after biological treatment. If the wastewater is hardly biodegradable or toxic to activated sludge pretreatment is an option.

Ozone can be used prior to a biological process[33] since it has a tendency to convert organic molecules into smaller more biodegradable species. This can enhance the efficiency of the biological process. In addition, ozone treatment of wastewater increases the oxygen content of the water (unconverted oxygen and ozone that decomposes back to oxygen that was mixed with the water) which results in improvement in aerobic processes. While this benefit is well known in the literature it is difficult to practically apply since the amount of improvement is difficult to predict and pilot studies involving ozone and biological processes are difficult to carry out. In textile wastewater processes, a 20-30% improvement in the action of the biological system has been observed.

Ozone is effective in removing the color from all dyes used in textile processing. The amount of ozone can vary depending on a number of factors: how much color was removed in the biological process, the type of dye used, where ozone is applied in the process, etc. Knowing the proper amount of ozone required to meet the color removal objective for the receiving water body is critical to the economics of the ozone system. In general it is not easy to predict the amount of ozone required, so in virtually all cases where specific previous experience is not available, pilot testing is employed.

Tosik [34] has shown that about 1 mg ozone/mg dye is required to achieve 95% color removal, although this ratio varies by dye type. The ratio increases to about 1.5 for 100% removal. Reaction times were on the order of 10 minutes. In the textile industry a typical dosage might be 15 mg/l post biological treatment, but the levels could easily reach 25 mg/l. It is important to note that the ozone dose only needs to make the dye compound uncolored and not necessarily completely mineralize the material.

The equipment operates in a temperature range of 40-95 degrees F.

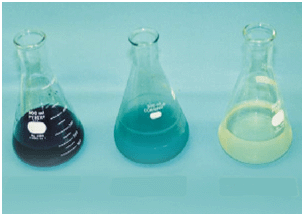

Treatment of reactive dyes and textile finishing wastewater using Fenton's oxidation for reuse

Fenton's oxidation (FO) was used to decolourise and degrade some reactive dyes (Remazol Black 5, Remazol Red, Remazol Blue, Remazol Yellow) and raw textile finishing industry effluents (S1, S2, S3) containing mainly reactive dyes. The operational conditions for pH varied between 2.5 and 4.0 while temperature ranged from 30°C to 50°C. The concentrations of FeSO4 and H2O2 varied to a wide range (200–600 mg/l of FeSO4, 300–1000 mg/l of H2O2) depending on the type of the dyes and their mixture and textile additives used in the process. FO is highly effective for colour removal (>99%) for reactive dyes and (87–94%) for textile finishing wastewater. It can be applied as a pretreatment and the remaining total dissolved solids (TDS) can be removed by an additional advanced process, e.g. membrane process.

Removal of Vat Dyes from Textile Wastewater Using Biosludge

The textile industry is an industry of interest .Textile wastewaters contain a high concentration of both organic matter and colourants (dyes). Due to its properties, vat dye ( Vat Black 25, Vat Green 1, Vat Black 8, Vat Yellow 1, Vat Green 13 ,Vat Brown 1 is mainly used in the textile industry. At present, chemical treatment methods such as oxidation, ion exchange, precipitation, coagulation and adsorption are commonly used to remove colourants from textile wastewater, but the chemical and operating costs are high and solid wastes are produced (chemical-sludge waste). Conventional biological treatment processes such as activatedsludge system oxidation ponds and aerated lagoons are also used in the textile industry. Organic matter (BOD5) is easily removed by biological treatment processes, but the colourants remain in the wastewater. Over the last 20 years, research has concentrated on using microorganisms for the removal of colour from textile industrial wastewater. Biological colour removal ability was found in both aerobic and anaerobic microorganisms. The colourant removal mechanisms are due to adsorption or degradation, or both adsorption and degradation. Both living and dead microorganisms could adsorb colourants, such as azo, diazo and reactive dyes. Also both gram-negative and gram-positive biosludge bacteria showed an ability to remove colourants. However, all the researchers above used pure microorganisms to remove colour from the textile industrial wastewater. The colour removal efficiency of living biosludge(mixed microorganisms) was tested in a sequencing batch reactor (SBR) system under various hydraulic retention time (HRT) conditions.

Biosludge from a wastewater treatment plant was able to adsorb colourants, particularly vat dyes, from textile wastewater.Biosludge was collected from the recycle storage tank of a wastewater treatment plant. The biosludge was treated by washing with a 0.1 M acetate buffer (pH 6) and used as the resting biosludge. The biosludge was autoclaved at 121ºC for 15 min and was used as autoclaved biosludge.

Autoclaved and resting biosludge showed different adsorption abilities with different types of vat dyes. The adsorption ability of the biosludge increased with an increase in sludge age (solid retention time; SRT). Autoclaved biosludge showed the highest adsorption ability under acidic conditions (pH 3) while the resting biosludge showed the highest adsorption ability under neutral or weak alkaline conditions. The maximum colourant (Vat Black 25) adsorption capacities of autoclaved and resting biosludge with a sludge age of 24 days were 85.54 ± 0.5 and 37.59 ± 0.6 mg/g biosludge, respectively. Using a sequencing batch reactor (SBR) system, the biosludge was able to remove both organic matter and colourants from both textile and synthetic textile wastewaters. The removal efficiencies of the system increased with an increase in SRT of thesystem. The removal efficiency of the system with textilewastewater was lower than with synthetic textile wastewater.The advantages of SBR systemareas follows: Simple and cost effective; Ability to combine aerobic and anoxic phases in a single reactor; High degree of process flexibility in terms of sequence and cycle time; Near ideal quiescent settling conditions; More resistant to fluctuating influent loading.

Colourant Adsorption Test

The adsorption capacities of both the resting sludge and autoclaved biosludge were determined by the Jar Test System [35] using the STIWW containing various types of vat dyes. The colourant adsorption yields of both living and dead biosludge were analyzed by using Freundlich’s adsorption isotherm equation [35].

Chemical Analysis

The BOD5 (mg/L), COD (mg/L), mixed-liquor suspended solids (MLSS) (mg/L), suspended solids (SS) (mg/L), pH and dissolved oxygen (DO) of the influents and effluents were determined by using Standard Methods for the Examination of Water and Wastewater [36]. The colour intensity (Abs 608 nm) (units) (Abs 608 nm) (units) of the wastewater was determined in optical density as the absorbance at the wavelength at which absorption was maximum after dilution with 0.1 M phosphate buffer (pH 7).

Color removal

Decolorization was monitored by UV–Vis spectroscopic analysis. Decolorization of dye was followed by monitoring, changes in its absorption spectrum (λ610 nm for sulfur black) and comparing the results, to those of the respective controls. The pellet was discarded after centrifugation and clear solution was analyzed using the AGILENT UV visible recording spectrophotometer.

% Decolorization = Initial conc. of dye – Final conc. of dye/Initial conc. of dye X 100.

Removal of Direct Dyes from Aqueous Solution Using Various Adsorbents

Removal of direct dyes [direct yellow 50 (DY50), direct red 80 (DR80) and direct blue 71(DB71)] from an aqueous solution by different adsorbents such as activated carbon, raw kaolinite and montmorillonite was investigated. The adsorption isotherm data were fitted to the Langmuir isotherm. Parameters of the Langmuir isotherm have been determined using the adsorption data.

Treatment of textile dyeing and printing waste water by SEMICONDUCTOR PHOTOCATALYSIS

Dyes are extensively used in the textile industry. The colour which dues impart to water bodies is very undesirable to the water user for aesthetic reasons. The textile dyeing and printing industry have been recognized as one of the most polluting industries in India, which contribute towards the pollution of the water environment. The textile dyeing and printing industries effluent contain high COD and colour it was observed that, the pollution potential of the printing industries are negligible as compare to that of textile dyeing. Pollution of water resources is thus high, as their location is mostly on the banks of small river [37]. Thus their high demand of finding a potential advanced treatment process, which could be an economic and effective process treating coloured wastewater completely. Semiconductor photocatalysis is an attractive treatment for industrial wastewater. Semiconductor photocatalysis can be defined as the reaction in which the decomposition of organic substances in an aqueous solution by means of semiconductor like TiO2 or ZnO in presence of light. Semiconductor photocatalysis is an aqueous process where the water is integral part of the reaction residence time may vary from 100 to 150 minute, and the Chemical Oxygen Demand (COD) removal may typically about 50-60 % insoluble organic matter is converted to soluble organic compound which are turn in oxidizing and eventually converted to CO2 and water, without emission of NO2, SO2, HCl, furans, fly ash etc. Semiconductors are used to degrade the organic pollutant in water to less harmful materials. The removal of colour from wastewater is often more important than the removal of other organic colourless chemicals . Decolourization of effluent from textile dyeing and printing industry was regarded important, because of aesthetic and environmental concerns .The TiO2 and ZnO have photocatalytic properties to be promissing substrate for photodegradation of water pollution and show appropriate activity in the range of solar radiation.The overall benefits of the decolourization of textile industrial wastewater may include very interesting subject saving huge amount of water because textile dyeing industries are regarded as chemical intensive and water intensive. This type of industry has more pollutants and consumes a huge amount of water.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

Membrane Process Application to Dye Removal for Textile Wastewater

These comprise three categories, namely ultrafiltration, nanofiltration and reverse osmosis. A membrane is a permeable or semi-permeable phase, often known as a thin polymeric solid, which restricts the motion of certain species. Membrane, is a barrier that is to allow one component of mixture to permeate the membrane freely, while hindering permeation of other component. Membrane separation can be operated in two major modes that are the direction of feed stream to the orientation of membrane. They are known as dead end filtration and cross flow filtration [38]. Membrane separation process has the ability to clarify, concentrate and most importantly, to separate dye continuously from effluent [39]. Wu et al. [40] used membrane and combined with ozonation process for treatment of reactive-dye wastewater. Membrane separation process generated a permeate with over 99% of colour and copper removed. While 85 % of salt and 85% of the original water were reusable. The major drawback are high capital costs combined with high energy costs.

[V] Factors Affecting Dye Biodegradation

Due to the highly variable nature of biological treatment systems and especially textile effluents, there are a number of factors that may affect the biodegradation rate of azo dyes. Non-dye related parameters such as temperature, pH, dissolved oxygen or nitrate concentrations, type and source of reduction equivalents, bacteria consortium, and cell permeability can all affect the biodegradation of azo dyes and textile effluents. Dye related parameters such as class and type of azo dye (i.e. reactive-monoazo), reduction metabolites, dye concentration, dye side-groups, and organic dye additives could also affect the biodegradability of azo dye wastewaters.

The azo dye structure can play a significant role in the dye biodegradation rate. Cell permeability might play an important role in dye biodegradation. Depending on the number and placement of the azo linkages, some dyes will biodegrade more rapidly than others. In general, the more azo linkages that must be broken will cause the reduction rate to be slower.

[ VI ] CONCLUSION

Due to the stability of modern dyes, conventional biological (activated sludge) treatment methods for indusrial wastwater are ineffective, resulting in an intensively coloured discharge from the treatment facilities. Thus, there is a need for developing treatment methods that are more effective in eliminating dyes from waste stream at its source. The novel processes described will need to be used in tandem with traditional methods in order to remove the additional pollutants present in effluent. This should provide a complete and environmentally friendly processes for remediating textile effluent.

Finally, operational costs will need to assessed by taking into account all of the expenses involved in implementing an industrial teratment facility.

ACKNOWLEDGMENTS

Dr. R. Krishnamurthy

Director, Bhagwan Mahavir College of Biotechnology.

REFERENCES

[1] Gupta V.K., Mittal A. and Gajbe V. “Adsorption and desorption studies of a water soluble dye, Quilnoline Yellow, using waste materials” Journal of Colloid and Interface Science 284: 89–98 (2005)

[2] Y. Anjaneyulu, N. S. Chary, D. S. S. Raj. Decolourization of industrial effluents – available methods and emerging technologies – a review. Reviews in Environmental Science and Bio Technology. Vol 4: 245 – 273 (2005)

[3] J.W. Choi, H.K. Song, W. Lee, K.K. Koo, C. Han, B.K. Na. Reduction of COD and Colour of Acid and Reactive Dyestuff Wastewater Using Ozone. Korean J. Chem. Eng. Vol 21(2), 398 – 403 ( 2004)

[4] Y. C. Chung, C. Y. Chen. Degradation of azo dye reactive violet 5 by TiO2 photocatalysis. Environ Chem Letter., Vol 7(4), 347-352 (2008)

[5] S. Sharma, S. Parthak, K.P. Sharma. Toxicity of azo dye methyl red to the organisms in micro systems with special reference to the guppy (Poecillia Reticulate Peters). Bull Environ Contam Toxicol.. Vol 70: 753 – 760 (2003)

[6] G.M. Walker, L. Hansen, J.A. Hanna, S.J. Allen. Kinetics of reactive dye adsorption onto dolomitic sorbents. Wat Res. Vol 37, 2081-2089 . (2003)

[7] S.F. Kang, C.H Liao, S.T. Po. Decolourization of Textile Wastewater by Photo-Fenton Oxidation Technology. Chemosphere. Vol 41, 1287 – 1295 (2000)

[8] W. G. Kuo. Decolourizing Dye Wastewater with Fenton’s reagent. Water Research. Vol 26 (7), 881- 886 ( 1992)

[9] S.H. Kim, T.W. Kim, D.L. Cho, D.H. Lee, J.C Kim, H Moon. Application of Characterization Procedure in Water and Wastewater Treatment by Adsorption. Korean J. Chem. Eng. 2002. Vol 19, 895-891

[10] Raffi, F., Hall, J.D.& Cernigila, C.E. Mutagenicity of azo dyes used in foods, drugs and cosmetics before and after reduction by Clostridium species from the human intestinal tract. Food and chemical Toxicology 35, 897 - 901. (1997)

[11] Aksu Z. “Application of biosorption for the removal of organic pollutants: a review”Process Biochemistry 40: 997–1026 (2005)

[12] Gupta V.K., Suhas I.A. and Mohan D. “Equilibrium uptake and sorption dynamics for the removal of a basic dye (basic red) using lowcost adsorbents” Journal of Colloid and Interface Science 265: 257–264 (2003)

[13] Robinson, T., G. McMullan G, R. Marchant, P. Nigam. Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Journal of Bioresource Technology, Vol 77, pp 247 – 255. (2001)

[14] C.I. Pearce, J.R. Lloyd, J.T. Guthrie, The removal of colour from textiles wastewater using whole bacteria cells: a review, Dye and Pigments 58 179-196. (2003)

[15] T.Robinson, G. McMullan, R. Marchant, P. Nigam, Remediation of dyes in textiles effluent: a critical review on current treatment technologies with a proposed alternative, Bioresource Technology, 77 247-255. (2001)

[16] M. Ghoreishi and R. Haghighi, Chemical catalytic reaction and biological oxidation for treatment of non-biodegradable textile effluent Chemical Engineering Journal, 95 163-169. (2003)

[17] Y. Fu and T. Viraraghavan, Fungal decolorization of dye wastewaters: a review, Bioresource Technology, 79 251-262. (2001)

[18] K.G. Bhattacharyya, A. Sharma, Adsorption characteristics of the dye, Brilliant Green

[19] G. McMullan, C. Meehan, A. Conneely, N.Kirby, T.Robinson, P.Nigam, I.M. Banat, R. Marchant, W.F.Smyth, Microbial decolourisation and degradation of textiles dyes, Application Microbial Biotechnology, 56 81-87. (2001)

[20] Razo-Flores E., M. Luijten, B. Donlon, G. Lettinga, J. Field, Biodegradation of Selected Azo Dyes under Methanogenic Conditions. Water ScienceTechnology, 36(6-7): 65-72. (1997)

[21] Weber, J. Eric and N. Lee Wolfe, Kinetic Studies of the Reduction of Aromatic Azo Compounds in Anaerobic Sediment/Water Systems. Environmental Toxicology and Chemistry, 6:911-919. (1987)

[22] Zissi U., G. Lyberatos, and S. Pavlous. Biodegradation of p-aminobenzene by Bacillus subtilis under aerobic conditions. Journal of Industrial Microbiologyand Biotechnology, 19:49-55. (1997)

[23] Loyd, K. Chapman, Anaerobic/Aerobic Degradation of a Textile Dye Wastewater. Masters Thesis, Virginia Polytechnic Institute and State University, 184 pp. (1992)

[24] Shaul, M. Glenn, T.J Holdsworth, C.R Dempsey, K.A Dostal, 1991. Fate of Water Soluble Azo Dyes in Activated Sludge Process. Chemosphere, 2(1-2):107-119.

[25] Yang Y, D.T Wyatt, M. Bahorshky, Decolorization of Dyes Using UV/H2O2 Photochemical Oxidation. Textile Chemist and Colorist, 30:27-35. (1998)

[26] Brown D. and P. Laboureur, The Aerobic Biodegradability of Primary Aromatic Amines. Chemosphere, 12(3): 405-414. (1983)

[27] A. Dabrowski, Adsorption — from theory to practice, Advances in Colloid and Interface Science, 93 135-224. (2001)

[28] Y. M. Slokar and A. Majcen Le Marechal, Methods of decoloration of textile wastewaters, Dyes and Pigments, 37 335-356. (1998)

[29] M.N.V. Kumar, T.R. Sridhari, K.D. Bhavani, P.K. Dutta, Trends in color removal from textile mill effluents. Bioresour. Technol, 77 25-34. (1998)

[30] Soares, G.M.B., Amorim, M.T.P. and Costa-Ferreira, M., “ Use of Laccase Together With Redox Mediators to Decolorize Remazol Brilliant Blue R J Biotechnol , 89,123-129, (2001)

[31] Kumar K.V., Sivanesan S. and Ramamurthi V. “Adsorption of malachite green onto Pithophora sp., a fresh water algae: equilibrium and kinetic modeling” Process Biochemistry 40: 2865–2872 (2005)

[32] V. Kumar, L. Wati, P. Nigam, I. M. Banat, B. S. Yadav, D. Singh and R. Marchant, Decolorization and biodegradation of anaerobically digested sugarcane molasses spent wash effluent from biomethanation plants by white-rot fungi, Process Biochemistry, 33 83-88. (1998)

[33] Removal of Dissolved Organic and color from dying Wastewater by Pre-Ozonation and Subsequent Biological Treatment, Takahashi, Nobuyuki; Kumagai, Tomoyo; Ozone: Science and Engineering, 28: 199-205

[34] Dyes Color Removal by Ozone and Hydrogen Peroxide: Some Aspects and Problems, R. Tosik, Ozone: Science and Engineering 27: 265-272 .

[35] Rubin AJ. Chemistry of wastewater technology. Ann Arbor Science Publishers, Inc., p. 245–281. (1978)

[36] APHA, AWWA, WPCF. Standard methods for the examination of water and wastewater, 16th ed., p. 3125–3250. American Public Health Association, New York. ( 1985)

[37] Sania, Helmy., Shadia, M. E.I.and Montaser Y.G., Bioremediation post photo-oxidation and coagulation for black liquor effluent treatment. Desallination, 158:331-339. (2003)

[38] Scott, K., and R. Hughes. Industrial Membrane Separation Technology. Blackie Academic & Professional, New York. (1996)

[39] Mantzavinos, D., R. Hellenbrand, A. G. Livingston, and I. S. Metcalfe. April Beneficial Combination of Wet Oxidation, Membrane Separation and Biodegradation Process for Treatment of Polymer Processing Wastewater. The Canadian Journal of Chemical Engineering, Vol 78. (2000)

[40] Wu, J, M. A. Eiteman, and S. E. Law. “Evaluation of Membrane Filtration and Ozonation Process for Treatment of Reactive-Dye Wastewater”. Journal of Environmental Engineering. Vol 124, No 3, March (1998)

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE