ABOUT AUTHORS:

Nitish Maini*, Saroj Jain, Satish Sardana

Hindu College of Pharmacy,

Sonipat, Haryana, India

*nitishmaini@yahoo.com

ABSTRACT

Patients who may otherwise be unable to take medication may benefit from new electronic implants capable of dispensing drugs automatically. The Remote Intelligent Drug Delivery System (RIDDS), a device implanted under the skin and connected to a wireless control center, overcomes the inconvenience associated with taking drugs manually. Such devices include built-in sensors that allow health care workers to monitor pulse rate, blood oxygen levels and other functions. Based on the information, they can adjust how frequently the medication is delivered or increase or decrease amounts as necessary. Nowadays, the Remote Intelligent Drug Delivery System (RIDDS) is a potential demand as they will be especially beneficial for people with physical or mental disabilities, who would otherwise be unable to take medications on their own.

REFERENCE ID: PHARMATUTOR-ART-1878

Introduction:

A microchip system has the ability to store a large number of drugs or chemicals, control the time at which release begins, and control the rate at which the chemicals are released. Drug delivery device is capable of controlled, pulsatile or continuous release of a wide variety of drugs that can be safely implanted inside the body. The microchip could be integrated with a tiny power supply and controlled by a microprocessor, remote control, or biosensors.It is simple to use and manufacture. It is multi welled so that drugs and other molecules can be delivered for weeks or years at a time It can hold many different drugs or other molecules of varying dosages and can release these substances in a controlled dependable manner.

Every human being to lead a long and a healthy life has always been the driving force behind various advancements in the biomedical field. The wireless communication field owing to rapid expansion has slowly started to make its presence being felt in various biomedical applications like remote healthcare monitoring, wireless drug delivery systems etc to name a few. In this era of increase in the aging population of the world, the wireless sensor nodes are gaining a lot of importance mainly because of the ease they offer in drug delivery and remote monitoring of patients. Patients suffering from chronic diseases need continuous monitoring and appropriate drug dosage delivery. Doing all these remotely reduces the burden on the already afflicted fellow humans. Moreover, the utilization of wireless sensor networks in these applications helps in controlling the spread of contagious infections (as the physical interaction with the affected patient is reduced).

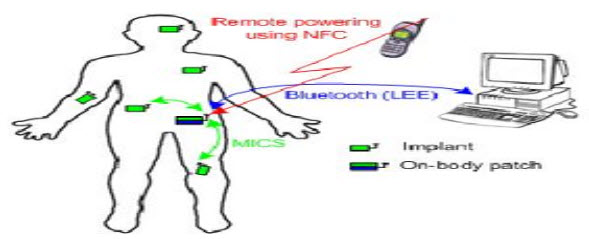

Figure 1: Drug release in body by Wireless technology/Remote technology

Microchip Device Design:

The microchip delivery system consists of a substrate containing multiple reservoirs which are capable of holding chemicals in the solid, liquid, or gel form. Each reservoir is capped with a conductive membrane and wired with the final circuitry. This is controlled by a microprocessor. The central processor should be able to control electrically the exact time of release and the amount of drugs dispersed by controlling the dissolution of the gold membrane.The design of a release system depends on the treatment required by the patient whether it is a continuous or pulsed release. Drug delivery can be achieved by a passive or active release system. In the passive system, the drugs diffuse through a membrane or enter the body by the degradation of the substrate. In the Active systems are triggered by a microprocessor and they are preferred due to a more predictable release profile. The exact time release and amounts of drugs can then be controlled.

Reservoir Caps:

It consists of anodes surrounded by cathodes. The portion of the anode directly above the reservoir oxidizes and dissolves into solution upon the application of a potential between the cathode and anode. This exposes the release system to the surrounding fluids and results in the release of the molecules or drugs. The requirement for the membrane material is that it should remain stable in the solution in the absence of an applied electric potential to prevent premature release of the chemical from the microchip.The membrane material should also be able to dissolve quickly and selectively when specific electric potential is applied. Gold is chosen as the membrane material because it is easily deposited, has low reactivity with other substances and resists corrosion in many solutions over the entire pH Range. presence of a small amount of chloride ion creates an electric potential region. This favours the formation of soluble gold chloride complexes. optimum anode potential is needed in order to release the chemicals from the reservoir.

Control Circuitry and Power Source:

The control circuitry consists of a timer, demultiplexer, microprocessor or an input source. The microprocessor will control the desired reservoir to be activated so that a variety of drugs may be contained in each specific reservoir. The input source can either be a memory source, remote control device or a biosensor. A thin-film microbattery can be used as a power source. All of these can be patterned directly onto the device.

Microfabrication:

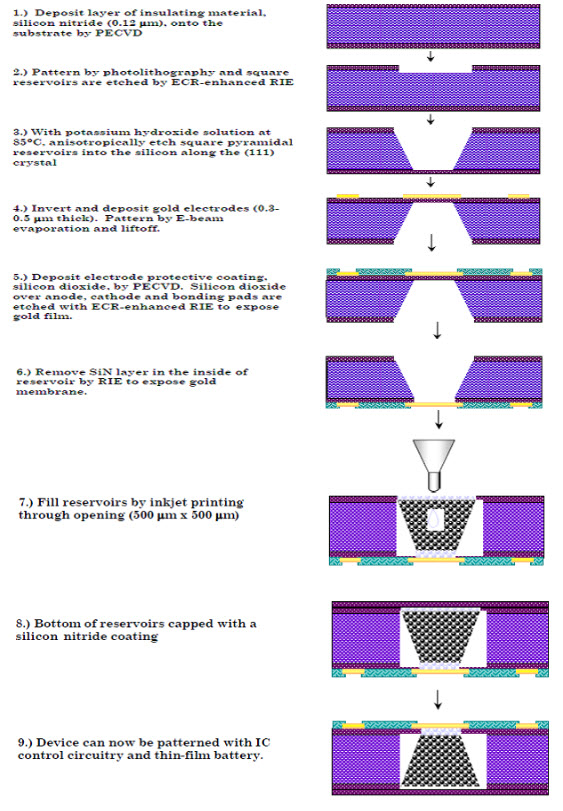

Figure 2: Fabrication of Microchip with filling of Drug

Working of Microchip:

It consists of anode and cathode Any number of cathodes can be included on a microchip, and they can be of any shape or size to suit the electrode design. Each reservoir is filled with a compound to be released. Open ends of the reservoirs are sealed with a Waterproof material. An electrical voltage is applied between the anode and a cathode to desired reservoir. Lithium rechargeable batteries are used.The anode membrane dissolves due to an electrochemical reaction. This reservoir is now open, allowing the material inside to diffuse out into the surrounding fluid. Each reservoir on the microchip can be activated and opened Individually. Each reservoir on the prototype microchip can be activated individually because each anode has its own independent connection to the power source. As the number of reservoirs on a microchip becomes large, it should be possible to connect each anode to the power supply through a demultiplexer. The demultiplexer serves as a "routing station" by directing power to a particular reservoir based on a code sent to the demultiplexer by a microprocessor or remote control.

Power Requirement General Circuit Design:

A biosensor will be used as the input source to the microprocessor. The microprocessor will have a programmed map of the drugs available in the reservoirs. These reservoirs will be interconnected in a multiplexing circuitry and will be activated by the microprocessor. A lithium thin film battery will be used as the power source.

Advantages of Microchip:

- Chemicals to be released

- Simplicity of release mechanism

- Accuracy of dose

- Improved shelf-life

- Complex release patterns

- Potential for local delivery

- Stability enhancement

Applications:

- This technology could be used in medical diagnostics or chemical detection and microfluidic devices for combinatorial chemistry or microbiology.

- It is used in drug delivery. This microchip may someday be used in the development of an autonomous, controlled release implant or a highly controllable tablet for oral drug delivery.

- The technology could be particularly useful for psychiatric and elderly patients who rely on a complicated regime of drugs and are at risk if they miss a dose or take it at a wrong time.

- Some Doctors conducted small clinical trials to seven Danish women with bone disease osteoporosis and they implanted chips under the skin for 20 days. This device released a dose of drug at a specific time each day, replacing the daily hormone injections currently used to manage the disorder. This implant removes the inconvenience of regular injections.

- The greatest benefit will come from patients receiving the right dose of the right medicine on time.

- An Ingestible microchip that will monitors your medication is interesting area of research with application of remote technology where the sand-particle sized sensor consists of a minute silicon chip containing trace amounts of magnesium and copper. When swallowed, it generates a slight voltage in response to digestive juices, which conveys a signal to the surface of a person's skin where a patch then relays the information to a mobile phone belonging to a healthcare-provider.

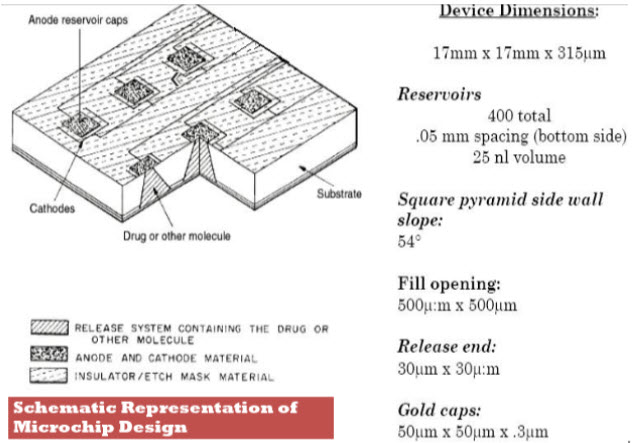

Figure 3: Generalized view of Microchip technology

Conclusion:

Microchip for drug delivery system is a potential system that allows the storage and dependable, controlled release of multiple drugs. This device is less complex and much more dependable than the devices that attempt to control drug release rate. The microchip can be created by general microfabrication techniques and can also be self-contained, which eliminates the need for patient or doctor intervention. The proposed device described can last over a year; however, the delivery abilities do depend on patients need. So, there is no second thought to the fact that these delivery system holds a lot of potential and offers an area which should be explored.

References:

1) wiki.epfl.ch/wban-radio

2) Jones DA. Principles and prevention of corrosion. Prentice Hall; Upper saddleriver. New Jersey.

3) Ratner BD, Hoffman AS. An introduction to materials in medicine. biomaterials science. Academic press.

4) Madou MJ. Fundamentals of Microfabrication Second edition. CRC Press.

5) singularityhub.com/2012/02/22/drug-delivery-microchip-implanted-in-patients-passes-human-trial/

6)Frankenthal RP, Siconolfi DJ. The anodic corrosion of gold in concentrated chloride solutions. Journal of Electrochemical Society.

7) genengnews.com/insight-and-intelligenceand153/drug-delivery-via-remote-control/77899642/

8) Wu BJ, Cima MJ. Effects of Solvent- Particle Interaction Kinetics on Microstructure Formation during Three- Dimensional Printing. Polymer Engineering and Science.

9) web.mit.edu/newsoffice/2012/wireless-drug-delivery-0216.html

10) Santini JT, Cima MJ, Langer RA. Controlled release microchip. Nature.

11) Merchant BH. Gold, the noble metal and the paradoxes of its toxicology. Biologicals.

12) Bates JB, Dudney NJ. Thin Film Rechargeable Lithium Batteries for Implantable Devices. ASAIO Journal.

13) io9.com/5930822/meet-the-future-of-medicine-an-ingestible-microchip-that-monitors-your-medications

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE