ABOUT AUTHOR:

K.Shailaja, Tahseen Sameena, S.P.Sethy, Prathima Patil, Md. Owais Ashraf,

Department Of Pharmaceutics.

Sushrut Institute of Pharmacy

Taddanpally (V), Pulkal (M), Medak-502293

shilu.kolmani@gmail.com

ABSTRACT:-

Carbon nanotubes have unique physical and chemical properties that chemists are trying to better understand through laboratory research. One of the physical properties of carbon nanotubes is that it’s possible to make them only a single atomic layer thick. This means that they can be about 1/50,000th the thickness of a human hair. Because of the bonding characteristics of carbon atoms, the physical appearance of carbon nanotubes can often resemble rolled up chicken wire. One of the interesting physical properties about carbon nanotubes is that when you have two of them which have slightly different physical structures and they are joined together, the junction (gap or small space) between them can function as an electronic device. This electronic behavior depends upon the structure of the two tubes. Currently scientists are trying to make carbon nanotubes in large amounts (high yield) with a high degree of purity (little or no material defects)so that the physical structures are all the same. If they have similar physical and chemical properties then it becomes easier to predict their behavior which would ultimately make them more useful for possible nano sensors. These nano sensors could behave like semiconducting materials in microelectronic circuits, or detect small changes in electric current, or register chemical reactivity, or changes in air pressure or temperature For a more detailed outline of the possible applications of carbon nanotubes see the further sections of this document. Since carbon nanotube science is relatively new, scientists from the fields of chemistry, physics and the material sciences are just beginning to unlock its mysteries and hypothesize about its potential applications.

[adsense:336x280:8701650588]

REFERENCE ID: PHARMATUTOR-ART-1995

INTRODUCTION:-

Carbon Nano tubes are the allotropes of carbon with a cylindrical nanostructure. Nanotubes have been constructed with length-to-diameter ratio of up to 132,000,000:1 significantly larger than for any other material. These cylindrical carbon molecules have unusual properties, which are valuable for nanotechnology, electronics, optics and other fields of materials science and technology. In particular, owing to their extraordinary thermal conductivity and mechanical and electrical properties, carbon nanotubes find applications as additives to various structural materials. For instance, nanotubes form a tiny portion of the material in some (primarily carbon fiber) baseball bats, golf clubs, or car parts[1].Nanotubes are members of the fullerene structural family. Their name is derived from their long, hollow structure with the walls formed by one-atom-thick sheets of carbon, called graphene. These sheets are rolled at specific and discrete ("chiral") angles, and the combination of the rolling angle and radius decides the nanotube properties; for example, whether the individual nanotube shell is a metal or semiconductor. Nanotubes are categorized as single-walled nanotubes (SWNTs) and multi-walled nanotubes (MWNTs). Individual nanotubes naturally align themselves into "ropes" held together by van der Waals forces, more specifically, pi-stacking. Applied quantum chemistry, specifically, orbital hybridization best describes chemical bonding in nanotubes. The chemical bonding of nanotubes is composed entirely of sp2 bonds, similar to those of graphite. These bonds, which are stronger than the sp3 bonds found in alkanes and diamond, provide nanotubes with their unique strength.

TYPES OF CARBON NANOTUBES:

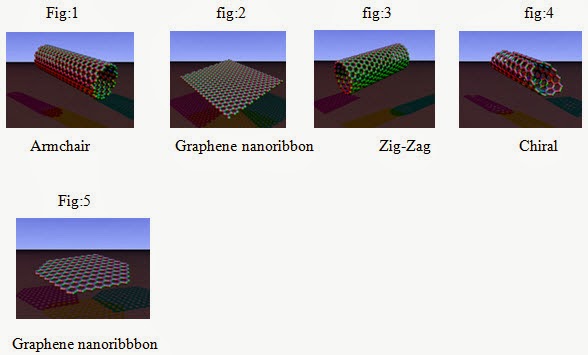

Carbon Nanotubes can be categorized by their structures:

1. Single Walled Nanotubes(SWNT)

2. Double Walled Nanotubes(DWNT)

3. Multi Walled Nanotubes(MWNT)

Single-Walled Nano Tubes:Most single-walled nanotubes (SWNT) have a diameter of close to 1 nanometer, with a tube length that can be many millions of times longer. The structure of a SWNT can be conceptualized by wrapping a one-atom-thick layer of graphite called graphene into a seamless cylinder. The way the graphene sheet is wrapped is represented by a pair of indices (n,m). The integers n and m denote the number of unit vectors along two directions in the honeycomb crystal lattice of graphene. If m = 0, the nanotubes are called zigzag nanotubes, and if n = m, the nanotubes are called armchair nanotubes. Otherwise, they are called chiral. SWNTs are an important variety of carbon nanotube because most of their properties change significantly with the (n,m) values, and this dependence is non-monotonic. In particular, their band gap can vary from zero to about 2 eV and their electrical conductivity can show metallic or semiconducting behavior. Single-walled nanotubes are likely candidates for miniaturizing electronics. The most basic building block of these systems is the electric wire, and SWNTs with diameters of an order of a nanometer can be excellent conductors[2]. One useful application of SWNTs is in the development of the first intermolecular field-effect transistors (FET). The first intermolecular logic gate using SWCNT FETs was made in 2001[3]. A logic gate requires both a p-FET and an n-FET. Because SWNTs are p-FETs when exposed to oxygen and n-FETs otherwise, it is possible to protect half of an SWNT from oxygen exposure, while exposing the other half to oxygen. This results in a single SWNT that acts as a NOT logic gate with both p and n-type FETs within the same molecule.

SINGLE WALLED NANOTUBES (SWNT)

DOUBLE WALLED NANOTUBES:

Double-wall nanotubes (DWNT) are an important sub-segment of MWNT. These materials combine similar morphology and other properties of SWNT, while significantly improving their resistance to chemicals. This property is especially important when functionality is required to add new properties to the nanotube. Since DWNT are a synthetic blend of both SWNT and MWNT, they exhibit the electrical and thermal stability of the latter and the flexibility of the former. Because they are developed for highly specific applications, SWNT that have been functionalized are more susceptible to breakage. Creating any structural imperfections can modify their mechanical and electrical properties. However, with DWNT, only the outer wall is modified, thereby preserving the intrinsic properties. Also, research has shown that DWNT have better thermal and chemical stability than SWNT. DWNT can be applied to gas sensors and dielectrics, and to technically-demanding applications like field-emission displays, nano composite materials, and nano sensors.

[adsense:468x15:2204050025]

MULTI WALLED NANOTUBES (MWNT):

Multi-walled nanotubes (MWNT) consist of multiple rolled layers (concentric tubes) of graphene. There are two models that can be used to describe the structures of multi-walled nanotubes. In the Russian Doll model, sheets of graphite are arranged in concentric cylinders, e.g., a (0,8) single-walled nanotube (SWNT) within a larger (0,17) single-walled nanotube. In the Parchment model, a single sheet of graphite is rolled in around itself, resembling a scroll of parchment or a rolled newspaper. The interlayer distance in multi-walled nanotubes is close to the distance between graphene layers in graphite, approximately 3.4 Å. The Russian Doll structure is observed more commonly. Its individual shells can be described as SWNTs, which can be metallic or semiconducting. Because of statistical probability and restrictions on the relative diameters of the individual tubes, one of the shells, and thus the whole MWNT, is usually a zero-gap metal.Double-walled carbon nanotubes (DWNT) form a special class of nanotubes because their morphology and properties are similar to those of SWNT but their resistance to chemicals is significantly improved. This is especially important when functionalization is required (this means grafting of chemical functions at the surface of the nanotubes) to add new properties to the CNT. In the case of SWNT, covalent functionalization will break some C=C double bonds, leaving "holes" in the structure on the nanotube and, thus, modifying both its mechanical and electrical properties. In the case of DWNT, only the outer wall is modified. DWNT synthesis on the gram-scale was first proposed in 2003 by the CCVD technique, from the selective reduction of oxide solutions in methane and hydrogen.The telescopic motion ability of inner shells[4] and their unique mechanical properties[5] will permit the use of multi-walled nanotubes as main movable arms in coming nanomechanical devices. Retraction force that occurs to telescopic motion caused by the Lennard-Jones interaction between shells and its value is about 1.5 nN[6].

TORUS:

In theory, a nanotorus is a carbon nanotube bent into a torus (doughnut shape). Nanotori are predicted to have many unique properties, such as magnetic moments 1000 times larger than previously expected for certain specific radii. Properties such as magnetic moment, thermal stability, etc. vary widely depending on radius of the torus and radius of the tube[7].

Fig:8

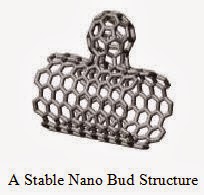

NANO BUD:

Carbon nanobuds are a newly created material combining two previously discovered allotropes of carbon: carbon nanotubes and fullerenes. In this new material, fullerene-like "buds" are covalently bonded to the outer sidewalls of the underlying carbon nanotube. This hybrid material has useful properties of both fullerenes and carbon nanotubes. In particular, they have been found to be exceptionally good field emitters. In composite materials, the attached fullerene molecules may function as molecular anchors preventing slipping of the nanotubes, thus improving the composite’s mechanical properties.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

GRAPHENATED CARBON NANOTUBES (g-CNTs):

Graphenated CNTs are a relatively new hybrid that combines graphitic foliates grown along the sidewalls of multi-walled or bamboo style CNTs. Yu et al[8].Reported on "chemically bonded graphene leaves" growing along the sidewalls of CNTs. Stoner et al.described these structures as "graphenated CNTs" and reported in their use for enhanced super capacitor performance. Hsu et al. further reported on similar structures formed on carbon fiber paper, also for use in super capacitor applications[9]. The foliate density can vary as a function of deposition conditions (e.g. temperature and time) with their structure ranging from few layers of graphene (< 10) to thicker, more graphite-like. The fundamental advantage of an integrated graphene-CNT structure is the high surface area three-dimensional framework of the CNTs coupled with the high edge density of graphene. Graphene edges provide significantly higher charge density and reactivity than the basal plane, but they are difficult to arrange in three-dimensional, high volume-density geometry. CNTs are readily aligned in high density geometry (i.e., a vertically aligned forest[10]) but lack high charge density surfaces—the sidewalls of the CNTs are similar to the basal plane of graphene and exhibit low charge density except where edge defects exist. Depositing a high density of graphene foliates along the length of aligned CNTs can significantly increase the total charge capacity per unit of nominal area as compared to other carbon nanostructures.

NITROGEN DOPED CARBON NANOTUBES:

Nitrogen doped carbon nanotubes (N-CNT's), can be produced through 5 main methods, Chemical Vapor Deposition[11], high-temperature and high-pressure reactions, gas-solid reaction of amorphous carbon with NH3 at high temperature, solid reaction, and solvothermal synthesis[12]. N-CNTs can also be prepared by a CVD method of pyrolysizing melamine under Ar at elevated temperatures of 800oC - 980oC. However synthesis via CVD and melamine results in the formation of bamboo structured CNTs. XPS spectra of grown N-CNT's reveals nitrogen in five main components, pyridinic nitrogen, pyrrolic nitrogen, quaternary nitrogen, and nitrogen oxides. Furthermore synthesis temperature affects the type of nitrogen configuration. Nitrogen doping plays a pivotal role in Lithium storage. N-doping provides defects in the walls of CNT's allowing for Li ions to diffuse into interwall space. It also increases capacity by providing more favorable bind of N-doped sites. N-CNT's are also much more reactive to metal oxide nanoparticle deposition which can further enhance storage capacity, especially in anode materials for Li-ion batteries[13]. However Boron doped nanotubes have been shown to make batteries with triple capacity.

PEAPOD:

A Carbon peapod[14] is a novel hybrid carbon material which traps fullerene inside a carbon nanotube. It can possess interesting magnetic properties with heating and irradiating. It can also be applied as an oscillator during theoretical investigations and predictions[15].

CUP-STACKED CARBON NANOTUBES:

Cup-stacked carbon nanotubes (CSCNTs) differ from other quasi-1D carbon structures, which normally behave as quasi-metallic conductors of electrons. CSCNTs exhibit semiconducting behaviors due to the stacking microstructure of graphene layers[16].

EXTREME CARBON NANOTUBES:

The observation of the longest carbon nanotubes (18.5 cm long) was reported in 2009. These nanotubes were grown on Si substrates using an improved chemical vapor deposition (CVD) method and represent electrically uniform arrays of single-walled carbon nanotubes. The shortest carbon nanotube is the organic compound cycloparaphenylene, which was synthesized in early 2009[17][18]. The thinnest carbon nanotube is armchair (2,2) CNT with a diameter of 3 Å. This nanotube was grown inside a multi-walled carbon nanotube. Assigning of carbon nanotube type was done by combination of high-resolution transmission electron microscopy (HRTEM), Raman spectroscopy and density functional theory (DFT) calculations[19]. The thinnest freestanding single-walled carbon nanotube is about 4.3 Å in diameter. Researchers suggested that it can be either (5,1) or (4,2) SWCNT, but exact type of carbon nanotube remains questionable. (3,3), (4,3) and (5,1) carbon nanotubes (all about 4 Å in diameter) were unambiguously identified using more precise aberration-corrected high-resolution transmission electron microscopy. However, they were found inside of double-walled carbon nanotubes[20].

Fig:9

Cycloparaphenylene

PROPERTIES OF CNTs

STRENGTH:

CNTs are not nearly as strong under compression. Because of their hollow structure and high aspect ratio, they tend to undergo buckling Carbon nanotubes are the strongest and stiffest materials yet discovered in terms of tensile strength and elastic modulus respectively. This strength results from the covalent sp2 bonds formed between the individual carbon atoms. In 2000, a multi-walled carbon nanotube was tested to have a tensile strength of 63 gigapascals (GPa). (For illustration, this translates into the ability to endure tension of a weight equivalent to 6422 kg (14,158 lbs) on a cable with cross-section of 1 mm2.) Further studies, such as one conducted in 2008, revealed that individual CNT shells have strengths of up to ~100 GPa, which is in agreement with quantum/atomistic models[21]. Since carbon nanotubes have a low density for a solid of 1.3 to 1.4 g/cm3, its specific strength of up to 48,000 kN·m·kg−1 is the best of known materials, compared to high-carbon steel's 154 kN·m·kg−1.Under excessive tensile strain, the tubes will undergo plastic deformation, which means the deformation is permanent. This deformation begins at strains of approximately 5% and can increase the maximum strain the tubes undergo before fracture by releasing strain energy.Although the strength of individual CNT shells is extremely high, weak shear interactions between adjacent shells and tubes leads to significant reductions in the effective strength of multi-walled carbon nanotubes and carbon nanotube bundles down to only a few GPa’s. This limitation has been recently addressed by applying high-energy electron irradiation, which crosslinks inner shells and tubes, and effectively increases the strength of these materials to ~60 GPa for multi-walled carbon nanotubes and ~17 GPa for double-walled carbon nanotube bundles. When placed under compressive, torsional, or bending stress.

HARDNESS:

Standard single-walled carbon nanotubes can withstand a pressure up to 25 GPa without deformation. They then undergo a transformation to superhard phase nanotubes. Maximum pressures measured using current experimental techniques are around 55 GPa. However, these new superhard phase nanotubes collapse at an even higher, albeit unknown, pressure.The bulk modulus of superhard phase nanotubes is 462 to 546 GPa, even higher than that of diamond (420 GPa for single diamond crystal[22]).

KINETIC PROPERTIES:

Multi-walled nanotubes are multiple concentric nanotubes precisely nested within one another. These exhibit a striking telescoping property whereby an inner nanotube core may slide, almost without friction, within its outer nanotube shell, thus creating an atomically perfect linear or rotational bearing. This is one of the first true examples of molecular nanotechnology, the precise positioning of atoms to create useful machines. Already, this property has been utilized to create the world's smallest rotational motor[23]. Future applications such as a gigahertz mechanical oscillator are also envisaged.

ELECTRICAL PROPERTIES:

Because of the symmetry and unique electronic structure of graphene, the structure of a nanotube strongly affects its electrical properties. For a given (n,m) nanotube, if n = m, the nanotube is metallic; if n − m is a multiple of 3, then the nanotube is semiconducting with a very small band gap, otherwise the nanotube is a moderate semiconductor. Thus all armchair (n = m) nanotubes are metallic, and nanotubes (6,4), (9,1), etc. are semiconducting.However, this rule has exceptions, because curvature effects in small diameter carbon nanotubes can strongly influence electrical properties. Thus, a (5,0) SWCNT that should be semiconducting in fact is metallic according to the calculations. Likewise, vice versa—zigzag and chiral SWCNTs with small diameters that should be metallic have finite gap (armchair nanotubes remain metallic). In theory, metallic nanotubes can carry an electric current density of 4 × 109 A/cm2, which is more than 1,000 times greater than those of metals such as copper, where for copper interconnects current densities are limited by electromigration. Because of their nanoscale cross-section, electrons propagate only along the tube's axis and electron transport involves quantum effects. As a result, carbon nanotubes are frequently referred to as one-dimensional conductors. The maximum electrical conductance of a single-walled carbon nanotube is 2G0, where G0 = 2e2/h is the conductance of a single ballistic quantum channel[24].There have been reports of intrinsic superconductivity in carbon nanotubes. Many other experiments, however, found no evidence of superconductivity, and the validity of these claims of intrinsic superconductivity remains a subject of debate.

OPTICAL PROPERTIES:

Carbon nanotubes are hollow tubes made entirely from carbon with diameters in the nanometer range such as the one shown in the picture below. Nanotubes are promising candidates for nano scale light-emitters and many other optical applications, especially in the infrared wavelength region of interest for e.g. optical communication. Because nanotubes can be both semiconductors and metallic depending on the diameter and “twist” they display highly interesting features.

EM WAVE ABSORPTION:

One of the more recently researched properties of multi-walled carbon nanotubes (MWNTs) is their wave absorption characteristics, specifically microwave absorption. Interest in this research is due to the current military push for radar absorbing materials (RAM) to better the stealth characteristics of aircraft and other military vehicles. There has been some research on filling MWNTs with metals, such as Fe, Ni, Co, etc., to increase the absorption effectiveness of MWNTs in the microwave regime.

THERMAL PROPERTIES:

All nanotubes are expected to be very good thermal conductors along the tube, exhibiting a property known as "ballistic conduction", but good insulators laterally to the tube axis. Measurements show that a SWNT has a room-temperature thermal conductivity along its axis of about 3500 W·m−1·K−1; compare this to copper, a metal well known for its good thermal conductivity, which transmits 385 W·m−1·K−1. A SWNT has a room-temperature thermal conductivity across its axis (in the radial direction) of about 1.52 W·m−1·K−1, which is about as thermally conductive as soil. The temperature stability of carbon nanotubes is estimated to be up to 2800 °C in vacuum and about 750 °C in air.

TOXICITY:

The toxicity of carbon nanotubes has been an important question in nanotechnology. Such research has just begun. The data are still fragmentary and subject to criticism. Preliminary results highlight the difficulties in evaluating the toxicity of this heterogeneous material. Parameters such as structure, size distribution, surface area, surface chemistry, surface charge, and agglomeration state as well as purity of the samples, have considerable impact on the reactivity of carbon nanotubes. However, available data clearly show that, under some conditions, nanotubes can cross membrane barriers, which suggests that, if raw materials reach the organs, they can induce harmful effects such as inflammatory and fibrotic reactions[25]. under certain conditions cnts can enter human cells and accumulate in the cytoplasm, causing cell death[26]. results of rodent studies collectively show that regardless of the process by which cnts were synthesized and the types and amounts of metals they contained, cnts were capable of producing inflammation, epithelioid granulomas (microscopic nodules), fibrosis, and biochemical/toxicological changes in the lungs[27]. Comparative toxicity studies in which mice were given equal weights of test materials showed that swcnts were more toxic than quartz, which is considered a serious occupational health hazard when chronically inhaled. As a control, ultrafine carbon black was shown to produce minimal lung responses. the needle-like fiber shape of cnts is similar to asbestos fibers. This raises the idea that widespread use of carbon nanotubes may lead to pleural mesothelioma, a cancer of the lining of the lungs or peritoneal mesothelioma, a cancer of the lining of the abdomen (both caused by exposure to asbestos). A recently published pilot study supports this prediction. scientists exposed the mesothelial lining of the body cavity of mice to long multiwalled carbon nanotubes and observed asbestos-like, length-dependent, pathogenic behavior that included inflammation and formation of lesions known as granulomas. Authors of the study conclude: this is of considerable importance, because research and business communities continue to invest heavily in carbon nanotubes for a wide range of products under the assumption that they are no more hazardous than graphite. Our results suggest the need for further research and great caution before introducing such products into the market if long-term harm is to be avoided. Although further research is required, the available data suggests that under certain conditions, especially those involving chronic exposure, carbon nanotubes can pose a serious risk to human health[28].

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

SYNTHESIS OF CNTs

Techniques have been developed to produce nanotubes in sizeable quantities, including arc discharge, laser ablation, high-pressure carbon monoxide disproportionation (HiPco), and chemical vapor deposition (CVD). Most of these processes take place in vacuum or with process gases. CVD growth of CNTs can occur in vacuum or at atmospheric pressure. Large quantities of nanotubes can be synthesized by these methods; advances in catalysis and continuous growth processes are making CNTs more commercially viable.

Fig:10

Powder Of Carbon Nanoparticles

ARC DISCHARGE:

Nanotubes were observed in 1991 in the carbon soot of graphite electrodes during an arc discharge, by using a current of 100 amps, that was intended to produce fullerenes. However the first macroscopic production of carbon nanotubes was made in 1992 by two researchers at NEC's Fundamental Research Laboratory[29]. The method used was the same as in 1991. During this process, the carbon contained in the negative electrode sublimates because of the high-discharge temperatures. Because nanotubes were initially discovered using this technique, it has been the most widely used method of nanotube synthesis. The yield for this method is up to 30% by weight and it produces both single- and multi-walled nanotubes with lengths of up to 50 micrometers with few structural defects.

LASER ABLATION:

In the laser ablation process, a pulsed laser vaporizes a graphite target in a high-temperature reactor while an inert gas is bled into the chamber. Nanotubes develop on the cooler surfaces of the reactor as the vaporized carbon condenses. A water-cooled surface may be included in the system to collect the nanotubes.This process was developed by Dr. Richard Smalley and co-workers at Rice University, who at the time of the discovery of carbon nanotubes, were blasting metals with a laser to produce various metal molecules. When they heard of the existence of nanotubes they replaced the metals with graphite to create multi-walled carbon nanotubes. Later that year the team used a composite of graphite and metal catalyst particles (the best yield was from a cobalt and nickel mixture) to synthesize single-walled carbon nanotubes[30]. The laser ablation method yields around 70% and produces primarily single-walled carbon nanotubes with a controllable diameter determined by the reaction temperature. However, it is more expensive than either arc discharge or chemical vapor deposition.

PLASMA TORCH:

Single-walled carbon nanotubes can be synthesized by the induction thermal plasma method, discovered in 2005 by groups from the University of Sherbrooke and the National Research Council of Canada[31]. The method is similar to the arc-discharge process in that both use ionized gas to reach the high temperature necessary to vaporize carbon containing substances and the metal catalysts necessary for the ensuing nanotube growth. The thermal plasma is induced by high frequency oscillating currents in a coil, and is maintained in flowing inert gas. Typically, a feedstock of carbon black and metal catalyst particles is fed into the plasma, and then cooled down to form single-walled carbon nanotubes. Different single-wall carbon nanotube diameter distributions can be synthesized. The induction thermal plasma method can produce up to 2 grams of nanotube material per minute, which is higher than the arc-discharge or the laser ablation methods.

CHEMICAL VAPOR DEPOSITION (CVD):

The catalytic vapor phase deposition of carbon was reported in 1952 and 1959, but it was not until 1993[32] that carbon nanotubes were formed by this process. In 2007, researchers at the University of Cincinnati (UC) developed a process to grow aligned carbon nanotube arrays of 18 mm length on a First-Nano ET3000 carbon nanotube growth system. During CVD, a substrate is prepared with a layer of metal catalyst particles, most commonly nickel, cobalt, iron, or a combination. The metal nanoparticles can also be produced by other ways, including reduction of oxides or oxides solid solutions. The diameters of the nanotubes that are to be grown are related to the size of the metal particles. This can be controlled by patterned (or masked) deposition of the metal, annealing, or by plasma etching of a metal layer. The substrate is heated to approximately 700°C. To initiate the growth of nanotubes, two gases are bled into the reactor: a process gas (such as ammonia, nitrogen or hydrogen) and a carbon-containing gas (such as acetylene, ethylene, ethanol or methane). Nanotubes grow at the sites of the metal catalyst; the carbon-containing gas is broken apart at the surface of the catalyst particle, and the carbon is transported to the edges of the particle, where it forms the nanotubes. This mechanism is still being studied. The catalyst particles can stay at the tips of the growing nanotube during the growth process, or remain at the nanotube base, depending on the adhesion between the catalyst particle and the substrate. Thermal catalytic decomposition of hydrocarbon has become an active area of research and can be a promising route for the bulk production of CNTs. Fluidised bed reactor is the most widely used reactor for CNT preparation. Scale-up of the reactor is the major challenge[33]. CVD is a common method for the commercial production of carbon nanotubes. For this purpose, the metal nanoparticles are mixed with a catalyst support such as MgO or Al2O3 to increase the surface area for higher yield of the catalytic reaction of the carbon feedstock with the metal particles. One issue in this synthesis route is the removal of the catalyst support via an acid treatment, which sometimes could destroy the original structure of the carbon nanotubes. However, alternative catalyst supports that are soluble in water have proven effective for nanotube growth. If a plasma is generated by the application of a strong electric field during the growth process (plasma enhanced chemical vapor deposition), then the nanotube growth will follow the direction of the electric field. By adjusting the geometry of the reactor it is possible to synthesize vertically aligned carbon nanotubes (i.e., perpendicular to the substrate), a morphology that has been of interest to researchers interested in the electron emission from nanotubes. Without the plasma, the resulting nanotubes are often randomly oriented. Under certain reaction conditions, even in the absence of plasma, closely spaced nanotubes will maintain a vertical growth direction resulting in a dense array of tubes resembling a carpet or forest. Of the various means for nanotube synthesis, CVD shows the most promise for industrial-scale deposition, because of its price/unit ratio, and because CVD is capable of growing nanotubes directly on a desired substrate, whereas the nanotubes must be collected in the other growth techniques. The growth sites are controllable by careful deposition of the catalyst. In 2007, a team from Meijo University demonstrated a high-efficiency CVD technique for growing carbon nanotubes from camphor. Researchers at Rice University, until recently led by the late Richard Smalley, have concentrated upon finding methods to produce large, pure amounts of particular types of nanotubes. Their approach grows long fibers from many small seeds cut from a single nanotube; all of the resulting fibers were found to be of the same diameter as the original nanotube and are expected to be of the same type as the original nanotube[34].

APPLICATION AND RELATED ISSUES:

Many electronic applications of carbon nanotubes crucially rely on techniques of selectively producing either semiconducting or metallic CNTs, preferably of certain chirality. Several methods of separating semiconducting and metallic CNTs are known, but most of them are not yet suitable for large-scale technological processes. The most efficient method relies on density-gradient ultracentrifugation, which separates surfactant-wrapped nanotubes by the minute difference in their density. This density difference often translates into difference in the nanotube diameter and (semi)conducting properties[35]. Another method of separation uses a sequence of freezing, thawing, and compression of SWNTs embedded in agarose gel. This process results in a solution containing 70% metallic SWNTs and leaves a gel containing 95% semiconducting SWNTs. The diluted solutions separated by this method show various colors. Moreover, SWNTs can be separated by the column chromatography method. Yield is 95% in semiconductor type SWNT and 90% in metallic type SWNT[36]. In addition to separation of semiconducting and metallic SWNTs, it is possible to sort SWNTs by length, diameter, and chirality. The highest resolution length sorting, with length variation of <10%, has thus far been achieved by size exclusion chromatography (SEC) of DNA-dispersed carbon nanotubes (DNA-SWNT). SWNT diameter separation has been achieved by density-gradient ultracentrifugation (DGU) using surfactant-dispersed SWNTs and by ion-exchange chromatography (IEC) for DNA-SWNT. Purification of individual chiralities has also been demonstrated with IEC of DNA-SWNT: specific short DNA oligomers can be used to isolate individual SWNT chiralities. Thus far, 12 chiralities have been isolated at purities ranging from 70% for (8,3) and (9,5) SWNTs to 90% for (6,5), (7,5) and (10,5)SWNTs. There have been successful efforts to integrate these purified nanotubes into devices, e. g. FETs. An alternative to separation is development of a selective growth of semiconducting or metallic CNTs. Recently, a new CVD recipe that involves a combination of ethanol and methanol gases and quartz substrates resulting in horizontally aligned arrays of 95–98% semiconducting nanotubes was announced[36]. Nanotubes are usually grown on nanoparticles of magnetic metal (Fe, Co), which facilitates production of electronic (spintronic) devices. In particular, control of current through a field-effect transistor by magnetic field has been demonstrated in such a single-tube nanostructure.

CURRENT APPLICATIONS OF CARBON NANOTUBES

CARBON NANOTUBES IN HEALTHCARE

Researchers have demonstrated artificial muscles composed of yarn woven with carbon nanotubes and filled with wax. Tests have shown that the artificial muscles can lift weights that are 200 times heavier than natural muscles of the same size. Nanotubes bound to an antibody that is produced by chickens have been shown to be useful in lab tests to destroy breast cancer tumors. The antibody-carrying nanotubes are attracted to proteins produced by one type of breast cancer cell. Once attached to these cells, the nanotubes absorb light from an infrared laser, tumor. Researchers at the University of Connecticut have developed a sensor that uses nanotubes and gold nanoparticles to detect proteins that indicate the presence of oral cancer. Tests have shown this sensor to be accurate and it provides results in less than a hour. Medical implants made of porous plastic, coated with carbon nanotubes are being used for drug delivery. Therapeutic drugs, which are attached to the nanotubes, can be released into the bloodstream, for example, when a change in the blood chemistry signals a problem. NASA is developing such an implant, called a "bio capsule", to protect astronauts from the effects of radiation. The implants may also be useful for releasing insulin in diabetic patients and for delivering chemotherapy drugs directly to tumors Improving the healing process for broken bones by providing a carbon nanotube scaffold that new bone material can grow around. Using nanotubes as a cellular scale needle to deliver quantum dots and proteins into cancer cells.

CARBON NANOTUBES AND THE ENVIRONMENT

Carbon nanotubes are being developed to clean up oil spills. Researchers have found that adding boron atoms during the growth of carbon nanotubes causes the nanotubes to grow into a sponge like material that can absorb many times it's weight in oil. These nanotube sponges are made to be magnetic, which should make retrieval of them easier once they are filled with oil. Carbon nanotubes can be used as the pores in membranes to run reverse osmosis desalination plants. Water molecules pass through the smoother walls of carbon nanotubes more easily than through other types of Nano pores, which requires less power. Other researchers are using carbon nanotubes to developed small, inexpensive water purification devices needed in developing countries. Sensors using carbon nanotube detection elements are capable of detecting a range of chemical vapors. These sensors work by reacting to the changes in the resistance of a carbon nanotube in the presence of a chemical vapor. An inexpensive nanotube-based sensor can detect bacteria in drinking water. Antibodies sensitive to particular bacteria are bound to the nanotubes, which are then deposited onto a paper strip. When the bacteria is present it attaches to the antibodies, changing the spacing between the nanotubes and the resistance of the paper strip containing the nanotubes. Carbon nanotubes tipped with gold nanoparticles can be used to trap oil drops polluting water. Since the gold end is attracted to water while the carbon end is attracted to oil. Therefore the nanotubes form spheres surrounding oil droplets with the carbon end pointed in, toward the oil, and the gold end pointing out, toward the water.

CARBON NANOTUBES EFFECTING MATERIALS:

Researchers are developing materials, such as a carbon nanotube-based composite developed by NASA that bends when a voltage is applied. Applications include the application of an electrical voltage to change the shape (morph) of aircraft wings and other structures. This video from NASA gives you ideas of what a futuristic morphing aircraft might look like. Researchers have found that carbon nanotubes can fill the voids that occur in conventional concrete. These voids allow water to penetrate concrete causing cracks, but including nanotubes in the mix stops the cracks from forming. Aircraft using carbon nanotubes to increase strength and flexibility in highly stressed components. A lightweight, low power anti-icing system using carbon nanotubes in a layer coated onto aircraft wing surfaces. Static dissipative plastic molding compounds containing nanotubes that can be used to make parts such as automobile fenders that can be electrostatically painted. Strong, lightweight composites of carbon nanotubes and other materials that can be used to build lightweight spacecraft. Cables made from carbon nanotubes strong enough to be used in building the Space Elevator to drastically reduce the cost of lifting people and materials into orbit.

CARBON NANOTUBES AND ELECTRONICS:

Building transistors from carbon nanotubes enables minimum transistor dimensions of a few nanometers and the development of techniques to manufacture integrated circuits built with nanotube transistors. Carbon nanotubes used to direct electrons to illuminate pixels, resulting in a lightweight, millimeter thick "nanoemissive" display panel. Printable electronic devices using nanotube "ink" in inkjet printers. Transparent, flexible electronic devices using arrays of nanotubes.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

STRUCTURAL APPLICATIONS

Because of the carbon nanotube's superior mechanical properties, many structures have been proposed ranging from everyday items like clothes and sports gear to combat jackets and space elevators[37][38]. However, the space elevator will require further efforts in refining carbon nanotube technology, as the practical tensile strength of carbon nanotubes can still be greatly improved. For perspective, outstanding breakthroughs have already been made. Pioneering work led by Ray H. Baughman at the NanoTech Institute has shown that single and multi-walled nanotubes can produce materials with toughness unmatched in the man-made and natural worlds. Carbon nanotubes are also a promising material as building blocks in bio-mimetic hierarchical composite materials given their exceptional mechanical properties (~1 TPa in modulus, and ~100 GPa in strength). Initial attempts to incorporate CNTs into hierarchical structures led to mechanical properties that were significantly lower than these achievable limits. Windle et al. have used anin situ chemical vapor deposition (CVD) spinning method to produce continuous CNT yarns from CVD grown CNT aerogels[39]. With this technology, they fabricated CNT yarns with strengths as high as ~9 GPa at small gage lengths of ~1 mm, however, defects resulted in a reduction of specific strength to ~1 GPa at 20 mm gage length. Espinosa et al. developed high performance DWNT-polymer composite yarns by twisting and stretching ribbons of randomly oriented bundles of DWNTs thinly coated with polymeric organic compounds. These DWNT-polymer yarns exhibited unusually high energy to failure of ~100 J·g−1 (comparable to one of the toughest natural materials – spider silk), and strength as high as ~1.4 GPa. Effort is ongoing to produce CNT composites that incorporate tougher matrix materials, such as Kevlar, to further improve on the mechanical properties toward those of individual CNTs.Because of the high mechanical strength of carbon nanotubes, research is being made into weaving them into clothes to create stab-proof and bulletproof clothing. The nanotubes would effectively stop the bullet from penetrating the body, although the bullet's kinetic energy would likely cause broken bones and internal bleeding.

ELECTRICAL CIRCUITS:

Nanotube-based transistors, also known as carbon nanotube field-effect transistors (CNTFETs), have been made that operate at room temperature and that are capable of digital switching using a single electron[40]. However, one major obstacle to realization of nanotubes has been the lack of technology for mass production. In 2001 IBM researchers demonstrated how metallic nanotubes can be destroyed, leaving semiconducting ones behind for use as transistors. Their process is called "constructive destruction," which includes the automatic destruction of defective nanotubes on the wafer. This process, however, only gives control over the electrical properties on a statistical scale. The potential of carbon nanotubes was demonstrated in 2003 when room-temperature ballistic transistors with ohmic metal contacts and high-k gate dielectric were reported, showing 20–30x higher ON current than state-of-the-art Si MOSFETs. This presented an important advance in the field as CNT was shown to potentially outperform Si. At the time, a major challenge was ohmic metal contact formation. In this regard, palladium, which is a high-work function metal was shown to exhibit Schottky barrier-free contacts to semiconducting nanotubes with diameters >1.7 nm. The first nanotube integrated memory circuit was made in 2004. One of the main challenges has been regulating the conductivity of nanotubes. Depending on subtle surface features a nanotube may act as a plain conductor or as a semiconductor. A fully automated method has however been developed to remove non-semiconductor tubes. Another way to make carbon nanotube transistors has been to use random networks of them. By doing so one averages all of their electrical differences and one can produce devices in large scale at the wafer level. This approach was first patented by Nanomix Inc. (date of original application June 2002). It was first published in the academic literature by the United States Naval Research Laboratory in 2003 through independent research work. This approach also enabled Nanomix to make the first transistor on a flexible and transparent substrate[41]. Large structures of carbon nanotubes can be used for thermal management of electronic circuits. An approximately 1 mm–thick carbon nanotube layer was used as a special material to fabricate coolers, this material has very low density, ~20 times lower weight than a similar copper structure, while the cooling properties are similar for the two materials. Overall, incorporating carbon nanotubes as transistors into logic-gate circuits with densities comparable to modern CMOS technology has not yet been demonstrated.

ELECTRICAL CABLES AND WIRES:

Wires for carrying electrical current may be fabricated from pure nanotubes and nanotube-polymer composites. Recently small wires have been fabricated with specific conductivity exceeding copper and aluminum[42]; these cables are the highest conductivity carbon nanotube and also highest conductivity non-metal cables.

PAPER BATTERIES:

A paper battery is a battery engineered to use a paper-thin sheet of cellulose (which is the major constituent of regular paper, among other things) infused with aligned carbon nanotubes[43]. The nanotubes act as electrodes; allowing the storage devices to conduct electricity. The battery, which functions as both a lithium-ion battery and a supercapacitor, can provide a long, steady power output comparable to a conventional battery, as well as a supercapacitor’s quick burst of high power—and while a conventional battery contains a number of separate components, the paper battery integrates all of the battery components in a single structure, making it more energy efficient.

SOLAR CELLS:

One of the promising applications of single-walled carbon nanotubes (SWNTs) is their use in solar panels, due to their strong UV/Vis-NIR absorption characteristics. Research has shown that they can provide a sizeable increase in efficiency, even at their current unoptimized state. Solar cells developed at the New Jersey Institute of Technology use a carbon nanotube complex, formed by a mixture of carbon nanotubes and carbon buckyballs (known as fullerenes) to form snake-like structures. Bucky balls trap electrons, but they can't make electrons flow[44]. Add sunlight to excite the polymers, and the Bucky balls will grab the electrons. Nanotubes, behaving like copper wires, will then be able to make the electrons or current flow. Additional research has been conducted on creating SWNT hybrid solar panels to increase the efficiency further. These hybrids are created by combining SWNT's with photexcitable electron donors to increase the number of electrons generated. It has been found that the interaction between the photoexcited porphrin and SWNT generates electro-hole pairs at the SWNT surfaces. This phenomenon has been observed experimentally, and contributes practically to an increase in efficiency up to 8.5%.

HYDROGEN STORAGE:

In addition to being able to store electrical energy, there has been some research in using carbon nanotubes to store hydrogen to be used as a fuel source. By taking advantage of the capillary effects of the small carbon nanotubes, it is possible to condense gases in high density inside single-walled nanotubes. This allows for gases, most notably hydrogen (H2), to be stored at high densities without being condensed into a liquid. Potentially, this storage method could be used on vehicles in place of gas fuel tanks for a hydrogen-powered car. A current issue regarding hydrogen-powered vehicles is the onboard storage of the fuel. Current storage methods involve cooling and condensing the H2 gas to a liquid state for storage which causes a loss of potential energy (25–45%) when compared to the energy associated with the gaseous state. Storage using SWNTs would allow one to keep the H2 in its gaseous state, thereby increasing the storage effciency. This method allows for a volume to energy ratio slightly smaller to that of current gas powered vehicles, allowing for a slightly lower but comparable range[45]. An area of controversy and frequent experimentation regarding the storage of hydrogen by adsorption in carbon nanotubes is the efficiency by which this process occurs. The effectiveness of hydrogen storage is integral to its use as a primary fuel source since hydrogen only contains about one fourth the energy per unit volume as gasoline.

EXPERIMENTAL CAPACITY:

One experiment sought to determine the amount of hydrogen stored in CNTs by utilizing elastic recoil detection analysis (ERDA). CNTs (primarily SWNTs) were synthesized via chemical vapor disposition (CVD) and subjected to a two-stage purification process including air oxidation and acid treatment, then formed into flat, uniform discs and exposed to pure, pressurized hydrogen at various temperatures. When the data was analyzed, it was found that the ability of CNTs to store hydrogen decreased as temperature increased. Moreover, the highest hydrogen concentration measured was ~0.18%; significantly lower than commercially viable hydrogen storage needs to be. In another experiment[46], CNTs were synthesized via CVD and their structure was characterized using Raman spectroscopy. Utilizing microwave digestion, the samples were exposed to different acid concentrations and different temperatures for various amounts of time in an attempt to find the optimum purification method for SWNTs of the diameter determined earlier. The purified samples were then exposed to hydrogen gas at various high pressures, and their adsorption by weight percent was plotted. The data showed that hydrogen adsorption levels of up to 3.7% are possible with a very pure sample and under the proper conditions. It is thought that microwave digestion helps improve the hydrogen adsorption capacity of the CNTs by opening up the ends, allowing access to the inner cavities of the nanotubes.

LIMITATIONS ON EFFICIENT HYDROGEN ADSORPTION:

The biggest obstacle to efficient hydrogen storage using CNTs is the purity of the nanotubes. To achieve maximum hydrogen adsorption, there must be minimum graphene, amorphous carbon, and metallic deposits in the nanotube sample. Current methods of CNT synthesis require a purification step. However, even with pure nanotubes, the adsorption capacity is only maximized under high pressures, which are undesirable in commercial fuel tanks.

ULTRA CAPACITORS:

MIT Laboratory for Electromagnetic and Electronic Systems uses nanotubes to improve ultracapacitors. The activated charcoal used in conventional ultracapacitors has many small hollow spaces of various size, which create together a large surface to store electric charge. But as charge is quantized into elementary charges, i.e. electrons, and each such elementary charge needs a minimum space, a significant fraction of the electrode surface is not available for storage because the hollow spaces are not compatible with the charge's requirements. With a nanotube electrode the spaces may be tailored to size—few too large or too small—and consequently the capacity should be increased considerably[47].

RADAR ABSORPTION:

Radars work in the microwave frequency range, which can be absorbed by MWNTs. Applying the MWNTs to the aircraft would cause the radar to be absorbed and therefore seem to have a smaller signature. One such application could be to paint the nanotubes onto the plane. Recently there has been some work done at the University of Michigan regarding carbon nanotubes usefulness as stealth technology on aircraft. It has been found that in addition to the radar absorbing properties, the nanotubes neither reflect nor scatter visible light, making it essentially invisible at night, much like painting current stealth aircraft black except much more effective. Current limitations in manufacturing, however, mean that current production of nanotube-coated aircraft is not possible. One theory to overcome these current limitations is to cover small particles with the nanotubes and suspend the nanotube-covered particles in a medium such as paint, which can then be applied to a surface, like a stealth aircraft[48].

MEDICAL:

In the Kanzius cancer therapy, single-walled carbon nanotubes are inserted around cancerous cells, then excited with radio waves, which causes them to heat