About Authors:

About Authors:

Vedant M. Pandya

Department of biotechnology, shree M & N Virani science college,

Rajkot, India-360005

vedantpandya007@gmail.com

ABSTRACT

A biosensor is a device for the detection of an analyte that combines a biological component with physicochemical detector components. An integrated device consisting of a biological recognition element & a transducer capable of detecting the biological reaction & converting it into a signal which can be processed. Ideally, the sensor shod be self-contained, so that it is not necessary to add reagents to the sample matrix to obtain the desired response. There are a number of analytes which are measured in biological media: pH, partial pressure of carbon dioxide, partial pressure of oxygen & the ionic concentration of sodium, potassium, calcium & chloride. Biosensors are typically classified by the type of recognition element or transduction element employed. Sensors might be described as a catalytic biosensor if it is recognition element comprised an enzyme or series of enzymes, a living tissue slice, or whole cells derived from microorganisms such as bacteria, fungi, or yeast. The sensor might be described as a bioaffinity sensor if the basis of operation were a biospecific complex formation. Accordingly, the reaction of an antibody with an antigen or hapten, or the reaction of an ageist or antagonist with a receptor, could be employed. In the former case, the sensor might be called an immunosensor. Since, enzyme-based sensor measure the rate of the enzyme-catalyzed reaction as the basis for their response, any physical measurement which yield a quantity related to this rate can be used for detection. The enzyme may be immobilized on the end of an optical fiber, & the spectroscopic properties related to the disappearance of the reactants or appearance of products of the reaction can be measured. Since biochemical reaction can be either endothermic or exothermic. Miniaturized thermistor based calorimeter called thermistos, have been developed & widely applied, especially for bioprocess monitoring.

[adsense:336x280:8701650588]

Reference Id: PHARMATUTOR-ART-1428

INTRODUCTION

In field of medicine, industry, agriculture, environment monitoring and biotechnology research, routine analyses using physical instruments are conducted for estimation and monitoring the levels of certain analytes (an analytes is a compound or molecule, whose presence and concentration needs to be Determined and monitored). Conventional physical methods for this routine analysis do not involve the use of any living organism or molecule of biological origin. However, for this purpose, biological molecule or living cells have been used to develop sensitive devices that are described as “Biosensors”. The biosensors have been considered to be superior and more sensitive, in comparison to physical instruments, due to the following reason: 1. In a biosensors, the immobilized biological material is present in intimate contact of a suitable transducer, so that the biochemical signal is quickly converted into an electrical signal. 2. The immobilization of bimolecular permits reuses of these molecules and allow simplification of the entire apparatus. 3. The biological sensing element is present in a small area and is very sensitive, thus facilitating analysis of substance in small quantities. 4. Biosensors may be developed according to specific needs and can be highly specific or broad spectrum.

The nature of interaction between the analyte and the biological material used in the biosensors may be of two type:

1) The analyte may be converted into a new chemical molecule (by enzyme; such biosensors are called catalytic biosensors), and

2) The analyte may simply bind to the biological present on the biosensor (e.g. to antibodies, nucleic acid; these biosensors are called affinity biosensors).

HISTORY OF THE DEVELOPMENT OF BIOSENSORS

The development of biosensors began in 1950, when a biosensor with an oxygen electrode (described as CLARK ELECTRODE)was developed by L. L. Clark in Cincinnati, USA to measure the dissolved oxygen in blood. Later, ‘glucose oxidase’ enzyme in a gel was coated and immobilized on the oxygen electrode to measure blood sugar. Similarly, enzyme ‘urease’ was used (in combination with an electrode specific for NH4++ ions) for measuring urea in body fluid like blood and urine. These two biosensors developed in early years of the history of biosensors made use of two transducer technologies. In the first case, the estimates were made by measurement of electric current (amperometric) & in the second case for urea measurements, the estimates were based on the measurement of charge on the electrode (potentiometer). The biosensors based on the use of enzyme involving catalytic action are called catalytic biosensors as against bioaffinity biosensors developed later, which do not make use of enzymes, but instead make use of antibodies, receptor molecule, etc., which have high affinity with the analyte. In 1980, the first bioaffinity biosensors were developed, in which radiolabel led receptors were immobilized on to a transducer surface. Biosensors based on ELISA have also been developed using labeled antibody or labeled antigen coupled with a suitable transducer.

‘WHOLE CELL BIOSENSORS’ were developed during 1980, making use of whole microbial cells or organelle. Similarly, small sensing organs like antennules have been used, to measure the level of various drug or environmental toxicants. Receptor molecules located in cell membranes have been isolated and in biosensors.

PRINCIPLE OF BIOSENSORS

A biosensor consists of (i) a biological component for sensing the presence & concentration of a substance & (ii) a transducer device, which works according to the principle. The principle is allowed to pass through a membrane so that selection may be exercised and the interfering molecules are retained outside the membrane. The sample then interacts with the biological sensor and from a product, which may be an electric current/charge, hest, gas or a suitable chemical. The product then passes through another membrane and reaches the transducer, which converts the biochemical signal into an electrical signal that can be further amplified and can be either read on digital panel or can be recorded over recorders. This allows the measurement of the concentration of a substrate without processing and thus avoiding consumption of the sample.

Biological material +Analyte

↓

Bound analyte

↓

Biological response

↓

Electric response

↓

Measurement

CHARACTERISTIC OF IDEAL BIOSENSORS

1) Small size

- Compact design for field use are possible

- Use in confined places such as needles and catheters IN VIVO is possible

- Can measure multiple analytes in a small sample

2) Fast measurement

· Waiting times for test results acceptably short

· High sample through put can be achieved in automated analyzer

3) Selected measurement in complex Sample

· Sample measurements in blood, foods, waste water, etc, are possible

· Sample may not need preparation prior to analysis

4) Targeted specificity

· Biosensors can be designed to detect either a single analyte with high specificity or a whole group of analytes

5) Manufacturable in large no. and at Low Cost.

· It must possible to manufacturability in large number

· Cost is also important factor for ideal Biosensor.

6) Continuous measurement

· Rapid Result within the timescale of the Process/diagnostic test.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

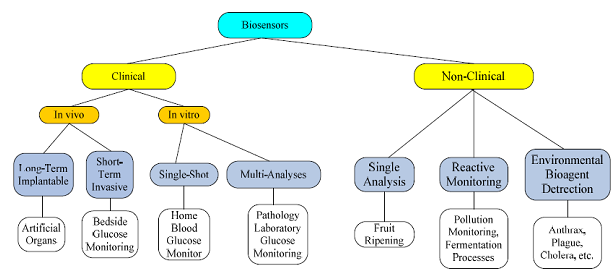

:: TYPES OF BIOSENSORS::

There are various types of biosensors based on the sensors devices & the types of biological material used.

1) AMPEROMETRIC BIOSENSORS

These biosensors are based on the movement of electron (i.e. determination of electric current) as a result of enzyme-catalyzed redox reaction. The simplest amperometric biosensors are using the Clark oxygen electrode, which determines the reduction of O2 present in the sample solution. These are the first generation biosensors. These biosensors are used to measure radox reactions, a typical example being the determination of glucose using glucose oxidase. In this case, the enzyme is separated from the electrode by a thin membrane that is only permeable to O2. Further, the enzyme is retained next to the electrode by means of a membrane, which is permeable to low molecular weight molecules, including the analyte and the products of the enzyme action. These biosensors suffer from the following drawback: (1) they can not be used in oxygen-deprived environments, e.g., in vivo, and (2) the electric potential used is sufficient to cause other redox processes like vitamin C oxidation/reduction to occur, which may interfere with the analyses.

The above difficulties may be overcome by using mediators, e.g., fluorescence: these molecules transfer the electrons generated by the reaction directly to the electrode rather than using them for reducing the O2 dissolved in the analyte solution; these are called second generation biosensors. A blood-glucose biosensors based on this strategy has breed produced and marketed; it can detect glucose concentration of 2-25mM in a single drop of blood and display the result within 30 second. These biosensors are widely used by people suffering from diabetes. A significant advance is represented by electrochemical oxidative polymerization of pyrolle into a membrane in which the enzyme and the mediator are entrapped together. Such membrane can be formed at the surface of even extremely small electrodes. This allows silicon chip micro fabrication method to be used, and for many different biosensors, e.g., glucose and lactate biosensors, to be laid down on the same electrode. The preset day electrode, removes the electrons directly from the reduced enzyme, and is coated with electrically conducting organic salts. The conducting organic salts consist of a mixture of two types of planar aromatic molecules, which serve as electron donors and electron acceptors, these salts partially exchange their molecules. The electrons, which have been partially transferred, are mobile up & down between the stake of donor & acceptor molecule. This gives the organic crystals a high conductivity. It is highly probable that these electrodes effectively behave as a highly insoluble mediator.

2) OPTICAL BIOSENSORS

Optical biosensors are the devices that utilize the principle of optical measurements (absorbance, fluorescence, chemiluminescence etc.). They employ the use of fiber optics and optoelectronic transducer. The word optrode, representing a condensation of the words optical & electrode, is commonly used. Optical biosensors primarily involve enzyme & antibody as transuding element.

Optical biosensors allow a safe non electrical remote sensing of material. Another advantage is that these biosensors do not required reference sensors, as the comparatively signal can be generated using the same source of light as the sampling sensors. Some of the important optical biosensors are briefly described hereunder.

Fiber optic lactate biosensors

Its working is based on the measurement of the changes in molecule O2 concentration by determining the quenching effect of O2on a fluorescent dye. The following reaction is catalyzed by the enzyme lactate monooxygenase.

O2 + Lactate

↓Lactate monooxygenase

CO2 + Acetate + H2O

The amount of fluorescence generated by the dyed film dependant on O2. This is because of O2 has a reducing effect on the fluorescence. As the concentration of lactate in the reaction mixture increase, O2 isutilized, an consequently there is a proportionate decrease in the quenching effect. The result is that there is an increase the fluorescent output which can be measured.

Optical biosensors for blood glucose

Estimation of blood glucose is very important for monitoring of diabetes. A simple technique involving paper strip impregnated with reagent is used for this purpose. This strip contains glucose oxidase, horse radish peroxidase & chromogen (e.g. Toluidine). The following reactions occur.

Glucose → Gluconic acid + H2O2 (1)

Chromogen + 2H2O2 → Colored dye + 2H2O (2)

Enzymes used in this reaction are:

(1) is Glucose oxidase

(2) is Peroxidase

The intensity of the color of the dye can be measured by using a portable Reflectance meter. Glucose strip production is a very big industry worldwide.

Colorimetric test strip of cellulose coated with appropriated enzyme & reagents are in use for the estimation of several blood & urine parameters.

Other optical biosensors

Optical fiber sensing devices are in use for measuring PH, PCO2 & PO2 in critical care, & surgical monitoring.

APPLICATION OF BIOSENSORS

Biosensors are suitable system for on-line measurement & continuous operations. They are small in size, easy to work, quick in action, very sensitive to measure tiny amount of test molecule & relatively very cheap. So they are put into many practical uses in medicine, industries & environmental control.

1) Medicine

A glucose biosensors coupled with a minipump containing insulin is used to detect blood glucose level directly & to deliver the accurate amount of insulin required by the diabetic. Usually enzyme electrode is used for this purpose.

Biosensors are also used in Pregnancy test. Detects the hCG protein in urine. Interpretation and data analysis performed by the user.

A few biosensors are employed to detect toxic substance & heavy Mattel in blood samples.

2) Industries

Biosensors are suitable for on-line measurement of certain compound in continuous industrial process. As they are very sensitive & quick in action, they have been put into many practical uses in industries.

The following are some important uses of biosensors in industries:

→ A microbial sensor made of immobilized cells of pseudomonas fluorescence & an oxygen electrode is used to detect glucose level in molasses.

→ The cell number of Bacillus subtilis in fermentation broth can be measured with a potentiometic biosensors.

→ a lactate sensor is used to count lactic acid producing bacteria in fermentation media. The lactate sensor is made up of an immobilized layer of lactate oxidase & a platinum electrode coupled with a volumetric device. Leuconostoc, Streptococcus & Lactobacillus are counted by this way.

→ an alcohol sensor is made up of immobilized layer of Trichsporon brassicae CBS 6382 & an oxygen electrode. It is used to measure methyl alcohol & ethyl alcohol in fermentation broth & beverages.

→ a formic acid sensor is made with immobilized layer of Clostridium butrycum & a fuel cell type electrode. It is used to measure formic acid level in fermentation broth.

→ Freeze dried cell of E.coli are immobilized on a silicon chip using a cellophane membrane. This sensor analyses glutamic acid in fermentation media.

3) Environmental control

Biosensors have been employed to detect the concentration of pollutants before going treat polluted water. As they can be automated, the quality control of drinking water & the assessment of pollution status are easy to workout sensitively.

The following sensors are much use in environmental control:

→ an ammonia sensor is made by coupling an immobilized layer of Nitrosomonas cell on an oxygen electrode. It measure ammonia level in water samples.

→ a nitrate sensor is made by coupling an immobilized layer of Nitrobacter on an oxygen electrode.

→ a sulfate sensor is made by immobilized microcosoms of Rat liver cell on oxygen electrode by using a porous acetyl cellulose membrane. It is used to detect sulfate & sulfur dioxide pollution in water.

4) Military

Biosensors have been developed to detect the toxic gases & other chemical agent used during war.

5) Drug discovery

Conventionally, drugs are discovered through a time consuming, tedious process. Biosensors have tremendous potential in speeding up this process. Biosensors can detect the interaction between a particular target and a possible drug without using markers or the detection of color changes or fluorescence. Biosensors can quickly measure how well a potential drug bind to a target & by eliminating markers; biosensors eliminate potential causes of interference. Test sample do not need to be purified & can be reused.

Biosensors also improve the accuracy of the result & are far less time consuming. For example, Prozac was introduced after 15 years of development, whereas a similar drug took two trails using biosensing technology. Texas Instrument is marketing a biosensnsing unit which can be useful for drug detection. The user “paints” some receptors or targets on the top of the device & runs a test. TI has demonstrated application in “refractive index change, avidin-biotin binding, antibody-antigen dissociation kinetics, thickness of insulators, refractive index of thin dielectronics, specific detection of small molecules, protein binding, concentration of analytes, attachment of DNA complements & mixture proportion.”

FUTURE PROSPECT

Ideal biosensors should possess a number of features. It is difficult & expensive to developed biosensors with all features. Therefore, selected features are incorporated in practical biosensors. This technology will be needed to provide early diagnosis of disease to maximize the benefits of treatment in healthcare & will be incorporated into application throughout science & engineering research. Also in future, processing the data from arrays of sensors will require access to faster, cheaper, & more flexible real-time data processing, combined with the best available data transmission & storage systems.

CONCLUSION

In order to facilitate this analytical revolution, biosensors technologists must resolve the remaining problems hindering the exploitation of biological molecule & their analogous in conjunction with microelectronics.Biosensors are cheap, small, and portable devices. So the strongly performance of biosensors depend on the sensing layer & we have spent time in designing & improving these layers.

REFERENCE

1) Biotechnology/ U. Satyanarayan/ 1st Edition/ 2005/ Chepter-21/ Page no. 297-305

2) Biotechnology/ S.S, Purohit/ 4th Edition/ Agrobios Publication/ 2005/ Chapter-39/ Page no. 929-937

3) Biotechnology/ R.C. Dubey/ S.Chand Publication/ 4th Edition/ 2006/ Chepter-22/ Page no. 522-529

4) Gor L. Medntz.et.al. (2003). “Self-Assembled Nenoscale Biosensors Based On Quantum Dot FERT Donors. VOL 2. Pg no. 630-637

5) San Francisco. (2009). “Inaugural Target Discovery World Congress 2009. VOL 1(7) . Pg no. 1211-1214

6) International Union of Pure and Applied Chemistry. "Biosensor". Compendium of Chemical Terminology Internet edition.

7) lsbu.ac.uk/biology/enztech/biosensors.html & mdpi.org/sensors

8) Encyclopedia of chemical technology, by Kirth and Othmer (vol.4) page no.208-220

9) bt.cdc.gov/

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to PharmaTutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE