About Authors:

About Authors:

Dhananjay S. Jadhav

M. Tech (Pharmaceutical Technology) Division of Pharmaceutical Technology,

School of Chemical Technology, North Maharashtra University,

Jalgaon- 425001, India

dhananjaysjadhav@hotmail.com

ABSTRACT

Oral administration of pharmaceuticals is one of the most popular method of drug dilevery.Taste is an important factor in the development of dosage form. “The worse the taste of the medication, the better the cure” was once the prevailing attitude. Many orally administered drugs elicite bitter taste. Undesirable and particularly bitter taste is one of the important formulation problems that are encountered with many drugs. Administration of bitter drugs orally with acceptable level of palatability is a key issue for health care providers. Proven methods for bitterness reduction and inhibition have resulted in improved palatability of oral pharmaceuticals. Several approaches like adding flavors and sweeteners, use of lipoproteins for inhibiting bitterness, coating of drug with inert agents, microencapsulation, multiple emulsion, viscosity modifiers, vesicles and liposomes, prodrug formation, salt formation, formation of inclusion and molecular complexes, solid dispersion system and application of ion exchange resins have been tried by the formulators to mask the unpleasant taste of the bitter drugs. The present review attempts to give a brief account of different technologies of taste masking with respect to dosage form and novel methods of evaluation of taste masking effect.

[adsense:336x280:8701650588]

Reference Id: PHARMATUTOR-ART-1535

INTRODUCTION

Taste is one of the most important parameter governing patient compliance. Undesirable taste is one of several important formulation problems that are encountered with certain drugs. Oral administration of bitter drugs with an acceptable degree of palatability is a key issue for health care providers, especially for pediatric patients. Several oral pharmaceuticals have unpleasant bitter tasting components. The desire of improved palatability in these products has prompted the development of numerous formulations with improved performance and acceptability (1, 2). To study various techniques of taste masking the basic information regarding taste sensation need to be understood.

THE SENSE OF TASTE:

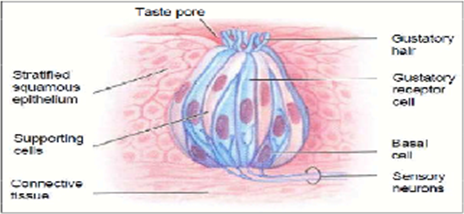

Taste is the ability to respond to dissolved molecules and ions “gatekeeper to the body”(3,4).Human detects taste with taste receptor cells that are clustered in to onion-shaped organs called taste buds. Each taste bud has a pore that opens out to surface of tongue enabling molecules and ions taken into the mouth to reach the receptor cells inside (5).

Human have around 10,000 taste buds which appear in fetus at about three months. A single taste bud contain 50-100 taste cells. These are transmembrane proteins which bind to the molecules and ions that give rise to the four primary taste sensations namely- salty, sour, sweet and bitter(6).

[adsense:468x15:2204050025]

1. The Taste Bud & Cells(7)

Recently, a fifth basic taste umami has been discovered. The umami is the taste of certain amino acids (6, 8). There is often correlation between the chemical structure of compound and its taste. Low molecular weight salts tend to taste salty where as high molecular weight salts tend toward bitterness. Nitrogen containing compounds, such as alkaloids, tend to be quite bitter. Organic compounds containing hydroxyl groups tend to become increasingly sweet as number of OH group increases. Receptor mechanism involves initial depolarization at apical receptor site, which causes local action potential in receptor cell. This in turn causes synaptic activation of the primary sensory neuron. Four basic taste are confirmed to specific regions of tongue (Table 1).But some workers deny the presence of specific regions of the tongue for a particular taste and consider it as a misconception (9) .

Fig 2.Taste receptor cells(10)

FOUR FUNDAMENTAL SENSATION OF TASTE HAVE BEEN DESCRIBED IN -

Fig.3 Taste points in tongue (11)

Salty Taste (Edge Upper Portion)

The salty taste is one among the four taste receptors of tongue .They are located on edge &upper front portion of the tongue.

Sweet Taste (Tip)

The sweet taste is one among the four taste receptor in the tongue .They are found on the tip of tongue.

Sour Taste (Along Sides In Back)

The sour taste is also one of four taste receptor of tongue. They occur at sides of tongue& are stimulated mainly by acids.

Bitter Taste (Back)

The bitter taste is last &one of four taste receptors in the tongue .That is located toward the back of tongue .It is stimulated by a variety of chemical substances,most of which are organic compound such as magnesium & calcium also produce bitter sensation.Recently, a fifth basic taste umami has been discovered. The umami is the taste of certain amino acids (12, 13). Threshold for taste is a minimum concentration of a substance that evokes perception of taste.

The following table 1 gives the threshold concentration of four primary taste sensation

|

Taste |

Area of tongue |

Threshold concentration ? |

|

Sweet(Sucrose) |

Tip |

0.5 |

|

Salt (NaCl) |

Edge upper portion |

0.25 |

|

Sour(HCL) |

Along sides in back |

0.007 |

|

Bitter(Quinine) |

Back |

0.0005 |

TABLE 1. SPECIFIC AREA OF TONGUE AND THRESHOLD CONCENTRATION FOR PRIMARY TASTE SENSATIONS (14)

APPROCHES TO OVERCOME BAD TASTE OF DRUGS (15)

Two approaches are commonly utilized to overcome bad taste of the drug.

1. Reduction of drug solubility in saliva ,where a balance between reduced solubility & bioavailability must be achieved.

2. To alter ability of drug to interact with taste receptor.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

AN IDEAL TASTE MASKING PROCESS AND FORMULATION SHOULD HAVE THE FOLLOWING

PROPERTIES (16)

1) Involve least number of equipments and processing steps.

2) Require minimum number of excipients for an optimum formulation.

3) No adverse effect on drug bioavailability.

4) Require excipients that are economical and easily available.

5) Least manufacturing cost.

6) Can be carried out at room temperature.

7) Require excipients that have high margin of safety

8) Rapid and easy to prepare

FACTORS THAT ARE TAKEN INTO CONSIDERATION DURING THE TASTE-MASKING FORMULATION PROCESS INCLUDE:

1) EXTENT OF THE BITTER TASTE OF THE API.

With aggressively bad tasting medicaments even a little exposure is sufficient to perceive the bad taste. For example, sweeteners could not achieve taste masking of oral formulation of ibuprofen due to its dominating taste. Coating is more efficient technology for aggressively bitter drugs even though coating imperfections, if present, reduce the efficiency of the technique(17) .Similarly, microencapsulation of potent bitter active agents such as azithromycin is insufficient to provide taste masking of liquid oral suspensions(18) .Conventional taste masking techniques such as the use of sweeteners, amino acids and flavoring agents alone are often inadequate in masking the taste of highly bitter drugs such as quinine, antibiotics like levofloxacin, ofloxacin, sparfloxacin, ciprofloxacin, cefuroxime axetil, erythromycin and clarithromycin(19).

2) REQUIRED DOSE LOAD.

Dose of a drug may dictate whether a particular formulation strategy would be suitable to achieve taste masking. In paediatric formulations, the dose is small enough so as to allow the usage of flavouring agents to mask the taste of the medicine. For example, low dose palatable paediatric aspirin oral formulation was developed by adding sweeteners, but the same approach failed to address the problem of drugs like acetaminophen because of its high dose. In such cases, coating is preferred to achieve taste masking along with sweeteners to attain an acceptable final dosage form size (20) .

3) DRUG PARTICULATE SHAPE AND SIZE DISTRIBUTION

Particle characteristics of the drug would affect the taste masking process efficiency. Core materials with irregular shapes and small particle size lead to poor taste masking efficiency and varying dissolution of coated particles. Fines, abrasion and variable coating thickness can lead to situations wherein the taste mask coating is compromised. Multilayer coating using inner spacing layer to sequester the drug from taste masking layer helps to reduce or eliminate such coating imperfections. Taste masked granules of gatifloxacin and dextromethorphan were formulated by multilayer coating consisting of inner spacing layer followed by outer taste masking layer.(21)

4) DRUG SOLUBILITY.

Physicochemical properties of the drug play an important role in the selection of taste masking technology. For example, ondansetron has a relatively lower water solubility at higher pH, based on which a rapidly disintegrating taste masked composition of ondansetron was formulated by adding an alkalizing agent(sodium bicarbonate) to reduce the water solubility and the consequent taste perception.The bitter taste associated with a poorly soluble form of ranitidine may be satisfactorily masked by lipid coating of the drug substance. However, for water soluble forms of ranitidine(e.g. ranitidine hydrochloride), the degree of taste masking achieved by simple lipid coating of the drug substance may not be entirely satisfactory, particularly if the product is to be formulated in an aqueous medium. Thus ranitidine hydrochloride was first incorporated into the inner core of a polymeric binder, or a lipid or wax having a melting point higher than that of the outer lipid coating to achieve an efficient taste masking (22).

5) IONIC CHARACTERISTICS OF THE DRUG:

Ionic characteristics of drugs govern the selection of ion exchange resin polymers and the suitability of the drug candidate for this technology. For example, anionic polymers (e.g. alginic acid) are good candidates for cationic drugs like donepezil hydrochloride, and the cationic polymers are choice of excipients for anionic drugs like sildenafil(23,24)

6) REQUIRED DOSAGE FORM

It is estimated that 50% of the population have problem of swallowing tablets, especially the paediatric and geriatric population. Chewable tablets and liquid oral dosage forms have been used to address these problems. However, it is difficult to formulate some drugs in these dosage forms due to their poor palatability. For formulations which are swallowed unchewed: capsules, coated tablets and slowly disintegrating hard tablets have been used as preferred taste masking technologies. Chewable tablets and liquid oral formulations are preferable in case of large dose drugs for an ease of intake. Taste masking technologies such as sweeteners, particulate coating, microencapsulation and granulation can be employed for chewable tablets and supported with technologies such as viscosity enhancers and pH modifiers to achieve taste masking in liquid oral formulations. Microencapsulation of the unpleasant tasting active agent with ethyl cellulose or a mixture of ethyl cellulose and hydroxypropyl cellulose or other cellulose derivatives has been used to provide chewable taste-masked dosage forms. However, this approach suffers from the disadvantage that the polymer coating releases the active agent in an inconsistent fashion and may not provide an immediate release. Moreover, coating is more suitable when the formulation is stored in a dry form. Viscosity enhancers or pH modifiers can be used in the suspending medium to achieve taste masking of suspended coated particles, especially for extremely bitter drugs like erythromycin and its derivatives during the shelf life of a reconstituted suspension (25).

GENERAL TASTE MASKING TECHNOLOGIES

To achieve the goal of taste abatement of bitter or unpleasant taste of drug. Various techniques reported in the literature are as follows:

1) Use Of Flavours And Sweeteners (26, 27)

This technique is the foremost and the simplest approach for taste masking, especially in the case of pediatric formulations, chewable tablets, and liquid formulations. But this approach is not very successful for highly bitter and highly water soluble drugs.

Using flavors from natural or synthetic sources, being simplest approach for taste masking, unpleasant taste of drugs modified. Flavors and sweeteners overwhelm the unpleasant taste by occupying the taste buds and thus suppressing the taste of drug. Flavors and sweeteners chosen based on their specific taste and release profiles e.g. Sweeteners like sodium saccharin, acesulfame potassium (aspartame) give instant sweetness, whereas sweeteners like monoammonium glycyrrhizate give lingering sweetness and used either alone or in combination.

A) Flavours

NATURAL FLAVORS

* Juices - Raspberry

* Extracts – Liquorices

* Spirits - Lemon & Orange

* Syrups – Blackcurrant

* Tinctures -Ginger

* Aromatic waters - Anise & Cinnamon

* Aromatic Oils – Peppermint & Lemon.

SYNTHETIC FLAVORS

* Alcoholic solutions

* Aqueous solutions

* Powders

BASIS OF CHOOSING A FLAVOR

* Complementary to existing flavor of the drug

* Known popularity of particular flavors

* Age of patients

* Allergy

FLAVOURING AGENTS FOR TASTE MASKING

|

BASIC TASTE |

MASKING AGENTS |

|

* Salt |

Butterscotch, maple, apricot, peach, vanilla, wintergreen mint. |

|

* Bitter |

Wild cherry, walnut, chocolate, mint, anise. |

|

*Ø Sweet |

Vanilla, fruit and berry. |

|

* Sour |

Citrus flavor, licorice, root beer, raspberry |

(B) SWEETNERS

* Complement flavors associated with sweetness

* Soothing effect on the membranes of the throat

* NATURAL SWEETENER

* Sucrose, glucose, fructose

* Sorbitol, mannitol, glycerol

* Honey, liquorice

* ARTIFICIAL SWEETENER

* Saccharin, Saccharin sodium

* Aspartame

* NUTRITIVE: Sucrose, Fructose and Glucose

* POLYOLS: Mannitol, Sorbitol, Xylitol, Erythritol, Maltitol.

* NON-NUTRITIVE: Aspartame, Sucralose, Neotame and Saccharine

* NOVEL SWEETENERS: Trehalose, Tagatose

LIST OF FDA APPROVED NON-NUTRITIVE SWEETENERS (sweetness factor, sucrose =1)

SR. NO SWEETENER SWEETNESS FACTOR

1 Aspartem 180-200

2 Acesulfame k 200

3 Saccharin 300

4 Sucralose 600

5 Neomate 7000-13000

2) TASTE MASKING BY MICROENCAPSULATION

It is important to understand that only soluble portion of the drug can generate the sensation of taste. And it is possible, or even likely, that coating the active drug with a properly selected polymer film can reduce its solubility in saliva in thus taste could be masked.Coating the drug particles created a physical barrier between the drug and the taste buds and this taste of active could be masked.(28,29)

Microencapsulation is a process by which very tiny droplets or particles of liquid or solid material are surrounded or coated with film or polymeric material.(30)

The goal of microencapsulation may be accomplished by any of following techniques(31)

* Air suspension coating

* Multiorifice-centrifugal process.

* Pan coating

* Interfacial polymerization

* Coacervation-phase separation

* Spray drying and spray congealing

* Solvent evaporation

3. TASTE MASKING BY INCLUSION COMPLEXATION (32)

In inclusion complex formation,the drug molecule fits into the cavity of a complexin agent ,i.e. the host molecule,forming a stable complex. The complexing agent is capable of masking the bitter taste of drug by either decreasing its oral solubility on ingestion or decreasing the amount of drug particles exposed to taste buds, thereby reducing the perception of bitter taste. This method is most suitable only for low dose drugs. Vander Walls forces are mainly involved in inclusion complexes. β-cyclodextrin is the most widely used complexing agent for inclusion type complexes. It is a sweet, non-toxic, cyclic oligosaccharide obtained from starch. The strong bitter taste of carbetapentane citrate syrup was reduced to approximately 50% by preparing a 1:1 complex with cyclodextrin1. Palatable ibuprofen solutions are prepared by forming a 1:11 to 1:15 inclusion complex with Ibuprofen and hydroxy propyl Bcyclodextrin, respectively.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

4. POLYMERS USED FOR COATING:

One of the most important factor to be considered in taste masking by coating is selection of coating polymers. Ideally, the coating polymers should be such that it prevents the release of active agent in the oral cavity, following per oral intake, but allows it in stomach or small intestine where the drug is expected to be absorbed. Polymers, which mainly insoluble at salivary pH 6.8 but readily, dissolves at gastric pH 1.2 could be a good candidate for taste masking.Choosing one of these polymers is not a simple selection. Before making a decision on coating material following factors must be considered.

* The particle size of drug

* flow characteristics of drug,

* moisture sensitivity, long term stability,

* temperature of processing

* method delivery of active drug molecule

Cushioning material like Avicel pH102,microcrystalline cellulose (MCC), can reduce the rupturing of microcapsule if used as direct compressible diluents.Once the type of coating and the plasticizers (if any) to use have been established then level of coating has to be optimized. If purpose of coating is taste masking, it may be simple taste panel to determine the proper coating level. Thick coating can cause problems both in terms of size and cost apart from being problematic in getting the desired release profile of the drug. However, by coordinating the right type of coating material. It is possible to completely mask the taste of bitter drug while at the same time, not adversely affecting the intended drug release profile.

Various coating materials for taste masking reported in literature are different grades of Eudragit, cellulose materials and waxes formulations(33).

5.TASTE MASKING BY GRANULATION:

Granulation is a less expensive, rapid operation and an easily scalable taste masking technology. This step can be exploited as a mean for taste masking of slightly bitter tasting drug. Granulation lowers the effective surface area of the bitter substance that come in contact with the tongue upon oral intake. Liquid and low melting point waxes such as glycerol palmitostearate, glyceryl behenate and hydrogenated castor oil are commonly used ingredients during the granulation to achieve taste masking.(34)

6.TASTE MASKING BY ION EXCHANGE RESINS

Based on Complexation of drugs with ion exchange resins. Ion exchange resins are water insoluble, cross linked high molecular weight polyelectrolytes containing salt forming groups in repeating position on the polymer chain which exchange their mobile ion of equal charge with the drug molecule. As taste perception of bitter drugs is experienced in the mouth at taste buds, complexed drugs resinate does not release drug in mouth due of scarcity of exchangeable ions (at pH 6.7) in the saliva and when complex comes in contact with GIT fluids (at acidic pH),complex is broken down quickly and drug is release.Resins being polyelectrolyte have extensive binding sites leading to very high drug loading ability Ion exchange resins have received considerable attention because of their versatile properties as drug delivery vehicles, chemically inert and free from local and systematic side effects possess long-term safety even while ingesting large doses and also compatible with all conventional solid, semisolid and liquid dosage forms. Ion exchange resin classified in four major groups, strong acid cation exchange resin, weak acid cation exchange resin, strong base anion exchange resin, weak base anion exchange resin. Majority of oral preparation containing bitter drugs use cation exchange resins for taste masking. Bitter cationic drugs get absorbed on to weak cationic exchange resins of carboxylic acid functionally to form the complex, which is non bitter.To bind the drug with resin, the drug repeatedly exposed with resin for prolonged contact and drug attached to the oppositely charged resin through weak ionic bond, so the dissociation of the drug-resin complex dose not occurs under salivary pH conditions, which suitably masks the unpleasant taste of drug. Strong acid cation exchange resins used for masking the taste of basic drug functions through out the entire pH range whereas weak acid cation exchange resin functions at pH more then six. Strong base cation exchangeresin function through out the entire pH range.

7. Use Of Amino Acids And Protein Hydrates:

By combining amino acids or their salts with bitter drugs, it is possible to substantially reduce the bitterness. Some of the preferred amino acids include sarcosine, alanine, taurine, glutamic acid, and glycine. The taste of ampicillin improved markedly by preparing its granules with glycine and mixing them with additional quantity of glycine, sweeteners, flavors and finally compressing them into tablets(35).

8. TASTE MASKING BY BITTERNESS INHIBITORS

The development of a specific universal inhibitor for bitter taste has been widely required in the fields of taste physiology and pharmaceutical sciences, but no such inhibitors has been available.One difficulty in discovering of universal inhibitor for bitter taste is that substances that inhibits bitterness of one compound will not influence the bitterness of a second because many different classes of compound impart bitterness. Sodium salts such as sodium chloride, sodium acetate, sodium gluconate have been shown to be potent inhibitors of some bitter compounds. The mechanism is not known, however, research shows that sodium act at peripheral taste level rather than a cognitive effect. Bitter substances are commonly hydrophobic in nature hence lipoprotein (PA?LG) composed of phophatidic acid and β lactoglobulin can mask the target sites for bitter substances on the taste receptor membrane without affecting responses to salts, acids, sugars or sweet amino acids.(36,37).

9. VISCOSITY MODIFICATION

Enhancement of viscosity in liquid formulations by thickening agents such as natural gums or carbohydrates can mask the unpleasant taste of drug by formulating a covering layer on the tongue and act as barrier between drug particles and taste buds, thus lowering the diffusion of drug from saliva into the taste buds13. For viscosity enhancement in liquid formulations, polyethylene glycols and carboxy methylcellulose are induced which not only increases the stability of liquid formulation but surprisingly, provides taste masking of unpleasant tasting medicines. For examples, in cough syrups, terbutaline given in doses of 4mg/5ml can be effectively administered by increasing the viscosity of the formulation(38).

10.TASTE MASKING BY PRODRUG APPROACH:

Chemical modification, including prodrug design is an effective method for reducing solubility, and thereby improving taste. A prodrug is chemically modified inert drug precursor which upon biotransformation liberates the pharmaceutically active parent compound. Bitterness of a molecule may be due to the efficiency of the taste receptor substrate adsorption reaction, which is related to the molecular geometry of the substrate. If alteration of the parent molecule occurs by derivative formation, the geometry is altered, affecting the adsorption constant. Thus the magnitude of a bitter taste response or taste receptor-substrate adsorption constant may be modified by changing the molecular configuration of the parent molecule. The extremely bitter antibiotics have been the focus of much work in reversible drug modification(39).

11. TASTE MASKING BY GELATION:

Water insoluble gelation on the surface of tablet containing bitter drug can be used for taste masking. Sodium alginate has the ability to cause water insoluble gelation in presence of bivalent metal ions. Tablet of amiprolose hydrochloride have been taste masked by applying a undercoat of sodium alginate and overcoat of calcium gluconate. In presence of saliva, sodium alginate reacts with bivalent calcium and form water insoluble gel and thus taste masking achieved(40).

12.DEVELOPMENT OF LIPOSOME:

Another way of masking the unpleasant taste of therapeutic agent is to entrap them into liposome. For example, incorporating into a liposomal formulation prepared with egg phosphatidyl choline masked the bitter taste of chloroquine phosphate in HEPES (N-2-hydroxyetylpiperzine-N’- 2- ethane sulfonic acid) buffer at pH 7.2(41).

13.TASTE MASKING BY ADSORPTION:

Adsorbates are commonly used in taste masking technologies. Adsorbate of bitter tasting drug can be considered as the less saliva soluble versions of these drugs. Adsorption involves preparing a solution of the drug and mixing it with an insoluble powder that will adsorb the drug, removing the solvent, drying the resultant powder, and then using these dried adsorbates in the preparation of the final dosage form. Many substrates like veegum, bentonite, silica gel and silicates can be used for the reparation of adsorbate of bitter drugs.The bitter taste of ranitidine is masked by forming an adsorbate with a synthetic cation exchange resin(42,43).

14. USE OF MULTIPLE EMULSION:

A novel technique of taste masking of drug employing multiple emulsion. The w/o/w or o/w/o type multiple emulsion are vesicular systems in which active ingredients can be entrapped in internal phase. The entrapped substances can be transferred from internal phase to external phase through the membrane phase. This phase controls the release of drug from system. These system could be used for controlled-release delivery of pharmaceuticals. If the system is stable enough for a reasonable shelf life, the formulation could also mask the taste of drug. Both w/o/w or o/w/o multiple emulsion of chloroquine phosphate have been prepared and reported to be partially effective in masking the bitter taste of drug(44,45).

15.MOLECULAR COMPLEXES OF DRUG WITH OTHER CHEMICALS:

The solubility and adsorption of drug can be modified by formation of molecular complexes.

Consequently lowering drug solubility through molecular complex formation can decrease the intensity of bitterness of drug Higuchi and Pitman, reported that caffeine forms complexes with organic acids that are less soluble than xanthan and as such can be used to decrease the bitter taste of caffeine(46,47)

16. MASS EXTRUSION METHOD:

This technology involves softening the active blend using the solvent mixture of water-soluble polyethylene glycol, using methanol and expulsion of softened mass through the extruder or syringe to get a cylinder of the product into even segments using heated blade to form tablets.The dried cylinder can also be used to coat granules of bitter tasting drugs and thereby masking their bitter taste(48,49).

17. USE OF SALTS OR DERIVATIVES:

In this approach, an attempt is made to modify the chemical composition of the drug substance itself, so as to the taste buds. Aspirin tablets can be rendered tasteless by making magnesium salt of aspirin. D-chlorpheniramine maleate is taste-masked salt of chlorpheniramine. The alkyloxy alkyl Carbonates of Clarithromycin have remarkably viated bitterness and improved bioavailability when administered[65]. Sodium salts such as sodium chloride, sodium acetate, sodium gluconate have been shown to be potent inhibitors of some bitter compound. The mechanism is not known, however, research shows that sodium act at peripheral taste level rather than a cognitive effect (50,51)

18. USE OF DESENSITIZING AGENTS

Desensitizing agents like phenols, sodium phenolates desensitize the taste buds by interfering with taste transduction the process by which taste message from the mouth to the brain and thus mask the taste of drug.(52)

[FIG. 4 TASTE BLOCKING MECHANISM]

19. WET SPHERICAL AGGLOMERATION (WSA)

Technique and Continuous Multipurpose (CMT) Technology. A novel microencapsulation process combined with the wet spherical agglomeration (WSA) technique was used to mask the bitter taste of enoxacin. The microcapsules prepared were bio-equivalent to the commercial Enoxacin 100 mg tablets in beagle dogs. The CMT method was developed for the continuous granulation and coating of pharmacologically active substances. It was concluded that this method could be successfully applied for taste masking of bitter drugs (53)

20 .PH MODIFIERS:

Many natural and synthetic polymers, resins and waxes alone or in combination have been employed for taste masking. The enteric polymers like eudragit L are used for taste masking but the pH of saliva is near 5.8 and these polymers solubilize at pH beyond 5.5 so there is a possibility of drug being partially leached. Therefore there is a need for the development of taste masking polymer such that the bitter taste is completely masked by the polymer at the pH of saliva in mouth and in the reconstitution medium as in case of the liquid orals and further which is able to protect the drug in a biologically active form, from the moisture in the dosage form and releasing the drug rapidly in the stomach without affecting its absorption and bioavailability.(54,55).

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

21. MISCELLANEOUS TASTE MASKING APPROACHES:

• BY EFFERVESCENT AGENTS

Effervescent agents have been shown to be useful and advantageous for oral administration of drugs and have been employed for use as taste masking agents for dosage forms that are not dissolved in water prior to administration. A chewing gum composition of bitter medicament was formulated to supply the medicament to oral cavity for local application or for buccal absorption. It comprise a chewing base, an orally administrable medicament, a taste masking generator of carbon dioxide, and optionally a taste bud desensitizing composition (e.g., oral anesthetic such as benzocaine) and other non active material such as sweeteners, flavoring components, and fillers.Recently, effervescent tablets of fentanyl and prochlorperazine were developed to supply these drugs to the oral cavity for buccal, sublingual, and gingival absorption. The formulation contains the drug in combination with effervescent agent to promote their absorption in the oral cavity and to mask their bitter taste. An additional pH adjusting substance was also included in fentanyl formulation for further promotion for absorption (56,57).

• RHEOLOGICAL MODIFICATION

Increasing the viscosity with rheological modifier such as gums or carbohydrates can lower the diffusion of bitter substances from the saliva to the taste buds. Acetaminophen suspension can be formulated with xanthan gum (0.1?0.2%) and microcrystalline cellulose (0.6?1%) to reduce bitter taste. The antidepressant drug mirtazapine is formulated as an aqueous suspension using methonine (stabilizer) and maltitol (thickening agent). Maltitol is stable in the acidic pH range of 2 to 3 and besides masking the unpleasant taste of the drug, it also inhibit its undesirable local anesthetic effect (58,59)

• CONTINUOUS MULTIPURPOSE MELT (CMT) TECHNOLOGY

The CMT method was developed for the continuous granulation and coating of pharmacologically active substances. It was concluded. That this method could be succesfully applied for taste masking of bitter drugs (60)

ADVANTAGES OF TASTE MASKING

1. To improve the patient compliance.

2. To improve the stability of some drug.

3. To improve the therapeutic efficacy and bioavaibility of certain drugs.

4. To improve the organoleptic properties of the drug.

EVALUATION TECHNIQUES:

SENSORY EVALUATION

Taste, to think of, is a very subjective perception. Depending on individuals, the perceived taste may vary to different degrees. If we have well controlled experimental set up, it is possible to accurately and reproducibly measures taste thresholds. To quantitativelyevaluate taste sensation, following methods have been reported in literature.

* Panel testing (human subjects)

* Measurement of frog taste nerve responses.

* Multichannel taste sensor/ magic tongue

* Spectrophotometric evaluation/ D30’s value

PANEL TESTING

The panel testing is a psychophysical rating of the gustatory stimuli. In this method, a group of about 5?10 human volunteers is trained for taste evaluation by using reference solutions ranging in taste from tasteless to very bitter. Numerical values are then assigned to these levels of bitterness (eg.,0?5). Subsequently, test solution is tasted and rated on the same scale to assess its bitterness. Literature reports panel testing in invariably all the taste?masked frugs being evaluated. The ease of the method combined with the accuracy of human perception of taste against any other gustatory evaluation technique makes panel testing the most commonly used technique(61).

• MEASUREMENT OF FROG TASTE NERVE RESPONSES

In this method, adult bull frogs are anaesthetized intraperitoneally and the glossopharyngeal nerve is then located and dissected from the surrounding tissue and cut proximally. An ac?amplifier and an electronic integrator are used to respectively amplify and integrate the nerve impulses. The peak height of the integrated response is then taken as the magnitude of response. Quinine sulphate formulations, taste masked by PA?LG(phosphatidic acid?lactoglobulin) combination have been reported to be evaluated by this technique(62).

• MULTICHANNEL TASTE SENSOR / MAGIC TONGUE

This is an automated taste sensing device to detect the magnitude of bitterness of a drug substance. The device has a transducer which is composed of several kinds of lipid/polymer membranes with different characterstics that can detect taste in a manner similar to human gustatory sensation. Taste response is transferred into a pattern composed of electric signals of membrane potentials of the receptor part. Different response electric potential pattern are obtained for substance producing different taste qualities. Recently, the technique has been applied, for the quantitative evaluation of the bitternessof some commercially available medicnes. Quinine hydrochloride was taken as the standard for bitterness. Basic drug with amino groups in the molecule such as quinine, show a comparitively good correlation between the relative response electric potential (mV) of channels 1 or 2 of the taste sensor, which contain negatively charged membranes, and the bitterness as determined by human gustatory sensations tests. Secondly, for anionic drugs, such as diclofenac sodium or salicylic acid, the positively charged membrane in channel 5 or 6 seemed to the useful even through they are being sour rather than bitter. For drugs with both an amino (cationic) groups and a carboxylic acid (anionic) group in the molecule, such as theophylline, caffeine and metronidazole, the electric potential (mV) of channel 1 or 2 did notincrease, even though bitterness was observed in human gustatory sensation test. Therefore, different types of membrane component will be needed for a complete evaluation of the bitterness of medicines(63,64).

• SPECTROPHOTOMETRIC METHOD

A known quantity of the taste?masked formulation is mixed with 10 ml of distilled water in 10 ml syringe by revolving the syringe,end to end, five times in 30 seconds.The test medium is then filtered through a membrane filter, followed by spectrophotometric determination of the concentration of the drug in the filtrate. If this concentration is below the threshold concentration, it may be concluded that the bitter taste would be masked in vivo. This technique has been applied to evalute the taste masked granules of sparfloxacin, with threshold concentration being 100μg/ml(65).

Conclusion:

There are number of technologies available which effectively mask the objectionable taste of drugs but require skilful application which does not affect the bioavailability of drug.With application of these techniques and proper evaluation of taste masking effect one can improve product preference to a large extent. Moreover, the development of taste masking methodology requires great technical skill, and the need for massive experimentation.

Acknowledgement:

The authors would like to acknowledge, to the Prof. Vinod Mokale Head of Division of Pharmaceutical Technology ,School of chemical Technology, North Maharashtra University Jalgaon for providing necessary facilities and encouragement.

References

1. Sohi H .Sultana Y and Khar R K. Drug Develop Ind Pharm 2004; 30(5): 429-48 Review Article Taste Masking of Bitter Drugs Using Different Techniques For Better Patient Compliance:AN Overview

2. Jha S K, Sharma R U, V Surendra. Journal Of Pharmacy Research. Oct-Dec.2008; Vol. 1,(2).: 126-129.

3. Cowart J B. Taste, Our Body’s Gustatory Gatekeeper. The DANA Foundation. April 01, 2005. Dana.Org

4. Boroditsky Lera. Taste, Smell And Touch : Lecture Notes. 27 July 2005. Accessed On 27 July 2010 Psych.Stanford.Edu/~Lera/Psych115s/Notes/Lecture11/

5. Sharma S Lewis S. Taste Masking Technologies: A Review. International Journal Of Pharmacy And Pharmaceutical Sciences.2010; 2(1):6-13.

6. Reineccius Gary, Heath H B. Flavor Chemistry And Technology. 2nd Ed. CRC Press, Taylor And Francis Group. ISBN 1-56676-933-7.2006

7. Taste masking of bitter drugs using different techniques for b etter patient compliance :overview .Nigarish Mizna*, Arora Vandana, Bhati Savita Journal of Pharmaceutical and Scientific Innovation Review Article

8. Culinaire Art. Umami: The Fifth Element-Fifth Element Of Taste. Food Industry. CBS Interactive Business Network. 2003 Accessed On 27 July 2010. Findarticles.Com/P/Articles/Mi_M0jaw/Is_69/Ai_105735781/

9. Guyton C. Hall J E. The Chemical Senses- Taste And Smell. In. Textbook Of Medical Physiology. Guyton And Hall Editors.11th Ed. Hong Kong; W.B. Saunders Company ;2007.

10. International Journal of Pharmacy and Pharmaceutical Sciences Vol 2, Issue 2, 2010, Taste Masking Technologies: A Review, Shalini Sharma And Shaila Lewis* Dept Of Pharmaceutics , Manipal College Of Pharmaceutical Sciences, Manipal University, Manipal 576 104, Karnataka, India

11. Dhakane K G ,Rajebahadur M C,Gorde Pm,Gade Ss. A novel approach for taste masking Techniques& evaluation in pharmaceutical: AN updated Review Asian journal J.biomed pharm sci 2011;1(3)?18-25)

12. Reineccius Gary, Heath H B. Flavor Chemistry And Technology. 2nd Ed. CRC Press,Taylor And Francis Group. ISBN 1-56676-933-7.2006.

13. Culinaire Art. Umami: The Fifth Element-Fifth Element Of Taste. Food Industry. CBS Interactive Business Network. 2003 Accessed On 27 July 2010. Findarticles.Com/P/Articles/Mi_M0jaw/Is_69/Ai_105735781/

14. Guyton C. Hall J E. The Chemical Senses- Taste And Smell. In. Textbook Of Medical Physiology. Guyton And Hall Editors.11th Ed. Hong Kong; W.B. Saunders Company ;2007

15. Brahmankar DM,Jaiswal SB Biopharmaceutics .First edition,1995;335,162-163,165

16. Chatap V K. A Review on Taste Masking Methods of Bitter Drugs. Pharmainfo.net

17. Kolter k,Scheiffele S,Einig H,Bodmeier R,US200100007680A1:2001

18. Catania JS,Johnson AD:US5633006;1997

19. Kulkarni GM,Menjoge AR:WU20050566119.2005

20. Roche,EJ,Papile SM,freeman EM;EP0473431.1995

21. Krise HE,Rajendra kk,johnH;US20046740341

22. Douglas SJ,Evans J;CA2146999.1994

23. Koji S,Kazuhiro N,Sakae S:SP161679.2004

24. Hisao F,Akiyoshi K,yasuyuki s,Takash K:JP2000119198

25. Mehata K,Mathur RS,SEthi SK,Malik R:WO2004096175.2004

26. Practical Approaches for Taste Masking of Bitter Drug: A Review Gupta A.K.1, Madaan S.1, Dalal M.1, Kumar A1, Mishra D.N.2, Singh S.K.2, Verma S.3

1M. M. College of Pharmacy, M. M. University, Mullana, Haryana (India)

2Department of Pharmaceutical Sciences, G. J. U. S & T., Hisar, Haryana (India)

3University Institute of Pharmaceutical Science, K.U.K, India International Journal of Drug Delivery Technology 2010; 2(2) 56-61 ISSN: 0975 4415

27. Mauger JW. Robinson J R. and Dennis H. US Patent 1998;5,728,403

28. Bakan J A. Capsules Part Iii. Microencapsulation. In. Lachmann L. The Theory And Practice Of Industrial Pharmacy. 3rd Ed.1986.412-429.

29. Kshirsagar S J. Pokharakar V B. Taste Masking Of Tinidazole And Optimization Of Microencapsulation Method. May 2006.Accessed On 27 July 2010. Pharmainfo.Net/Reviews/Taste-Masking-Tinidazole-And-Optimization- Microencapsulation-Method

30. Sharma S Lewis S. Taste Masking Technologies: A Review. International Journal Of Pharmacy And Pharmaceutical Sciences.2010; 2(1):6-13.

31.Lachman L, Lieberman H A. Kanig J L. Liquids. In. The Theory And Practice Of Industrial Pharmacy. Philadelphia; Lea And Febiger; 1987;419,47

32. Morella, A., Taste masked liquid suspensions. U.S. Patent 6 197 348. 6 March2001

33. Habib Y.S., Shangraw R.. Cushioning beads and tablet comprising the same capable of forming a suspension. U.S. Pat. No. 5,780,055 to University at Maryland, Baltmore; 1998.

34. 9. Zelalem A, Puri V, Kumar L, Bansal A. Trends in Pharmaceutical Taste Masking Technologies: A Patent Review. Recent Patents on Drug Delivery & Formulation 2009;3, 26-39.

35. Kasturagi Y, Sugiura Yc, Lee K, Otsugi And Kurihara. Pharm Res 12:1995; 658-662.

36. Russel, S.J., Paul, A.S. Suppression of bitterness using sodium salts. Flavours and Fragrances. 2001; 55: 441?447.

37. Breshlin, P.A.S., beauchamp, G.K. Suppression of bitterness by sodium variation among bitter taste stimuli. Chemical Senses. 1995; 20: 609?623.

38. International Journal of Drug Delivery Technology 2010; 2(2) 56-61 ISSN: 0975 4415 Review Article Practical Approaches for Taste Masking of Bitter Drug: A Review Gupta A.K.1, Madaan S.1, Dalal M.1, Kumar A1, Mishra D.N.2, Singh S.K.2, Verma S.

39. Josef H. Tsau and Nalinkant C. Damani.Taste masking compositions. US Patent No. 5286489, 1993

40. Kaning K, Kanada K. Application of gel formation for taste masking. Chem. Pharm. Bull 1997; 45: 1063-1068.

41. Kasturagi Y, Sugiura Y C, Lec. Otsugi K and Kurihara. Selective inhibition of bitter taste of various drugs by lipoprotein. Phram.Res. 1995; 12, 15:658-662

42. Sharma S, lewis S. Taste masking technologies: a review. International Journal of Pharmacy and Pharmaceutical Sciences, 2, 2010, 6- 13.

43. Stephen J. Douglas and Fiona R. Bird.Drug adsorbates.US Patent No. 5219563, 1993 .

44.Rao, M.Y., Bader,F. The Eastern Pharmacist.1991;123-124.

45. Vazliri,A. Warburton, B. Journal Of Microencapsulation.1994;11:641-648.

46 .Sharma S Lewis S. Taste Masking Technologies: A Review. International Journal Of Pharmacy And Pharmaceutical Sciences.2010; 2(1):6-13.

47. Lachman L. Theory And Practice Of Industrial Pharmacy. Third Edition,1986; 450-454

48. Meyer Ga And Mazer Tb. Taste Masking Technologies In Oral Pharmaceuticals: Recent Developments And Approaches. U.S.Patent 5599556, 1997

49. Sharma S Lewis S. Taste Masking Technologies: A Review. International Journal Of Pharmacy And Pharmaceutical Sciences.2010; 2(1):6-13

50. Russel, S.J., Paul, A.S. Flavors And Fragrances. 2001; 55: 441?447.

51. Breshlin, P.A.S., Beauchamp, G.K. Chemical Senses. 1995; 20: 609?623

52, Atish, S., Mundada, Chachda, O.Nilesh and Jasmine G.Taste masking approaches – A Review part- II. American pharmaceutical review. 1-3.

53. Asian Journal of Biomedical and Pharmaceutical Sciences 1 (3) 2011, 40-47. A Noval Approch For Taste Masking Techniques And Evaluations In Pharmaceutical, Update Review. Kiran G. Dhakane*, Minal C. Rajebahadur, Pradip M.Gorde, Sachin S. Gade. Department of Pharmaceutics, Shri Bh