About Authors:

About Authors:

*Tarun Patel, Prof. Dr. Vipin Kukkar, Arshad hala, Dhiren Shah

Seth G.L. Bihani S.D. College of Technical Education,

Institute of Pharmaceutical Sciences and Drug Research,

Sri Ganganagar, Rajasthan, INDIA

*tarunpatel35@gmail.com

ABSTRACTS:

In pharma industry containers and closures play important role for improving quality of pharma products in market. For improving quality of containers and closures there are different types of raw materials are used like glass, plastic, rubber, metal etc. Out of that all raw materials in manufacturing of containers and closures widely use is plastic because of its less interaction with product as compare to other materials. In this review articles we discuss about quality of containers and closures.

[adsense:336x280:8701650588]

Reference Id: PHARMATUTOR-ART-1511

1. INTRODUCTION

A pharmaceutical container is a device that drug and may be in direct contact with the product. If the container is in direct contact with the drugs it is called an immediate container. A closure seals the container to exclude air, dust, moisture, microorganism etc. and prevents the loss of liquid and other volatile substances from the product. Containers and closure are employed primarily to carry a preparation to protect it and at times to identity it. They afford consumer convenience and a device to the seller for transportation of dosage form. (Lockhart H.)

2. CONTAINERS

Containers for pharmacopeial articles must be chosen with care and after taking into consideration the nature of the articles and the likely effects of transportation and storage, even for short periods of time. A container for pharmaceutical use is an article that contains or is intended to contain a drug substance or a dosage form and is, or may be, in direct contact with it. The closure is a part of the container.

A container should be designed so that the contents may be removed in a manner suitable for the intended use of the article in it. It should also provide a suitable degree of protection, minimise the loss of constituents and should not interact physically or chemically with the contents in a way that will alter their quality to an extent beyond the limits given in the individual monograph.

The general requirements for containers of various types are given in the General Notices. This Appendix deals with the specific requirements, guidance and information on containers and also provides standards for the principle materials used for making pharmaceutical containers viz. glass, metal and plasticSpecifications for the container to be used for any article have not been given but in certain cases, the type of container that is recommended is stated in terms that have the following meanings.(IP-96,2007)

[adsense:468x15:2204050025]

Airtight container. A container that is impermeable to solids, liquids and gases under ordinary conditions of handling, storage and transport. If the container is intended to be opened on more than once, it must be so designed that it remains airtight after re-closure.

Hermetically Sealed container. A container that is impervious to air or any other gas under normal conditions of handling, shipment, storage and distribution, e.g. sealed glass ampoule, gas cylinder etc.

Light-resistant container. A container that protects the contents from the effects of actinic light by virtue of the specific properties of the material of which it is made. Alternatively, a clear and colourless or a translucent container may be made light-resistant by means of an opaque (light-resistant) covering and/or stored in a dark place; in such cases, the label on the container should bear a statement that the opaque covering or storage in dark place is needed until the contents have been used up.

Multidose container. A container that holds a quantity of the preparation suitable for two or more doses.

Sealed container. A container closed by fusion of the material of the container.

Single-dose container. A container that holds a quantity of the preparation intended for total or partial use as a single administration.

Tamper-evident container. A container fitted with a device or mechanism that reveals irreversibly whether the container has been opened.

Tightly-closed container. A tightly-closed container protects the contents from contamination by extraneous liquids, solids or vapours, from loss or deterioration of the article from effervescence, deliquescence or evaporation under normal conditions of handling, shipment, storage and distribution. A tightly-closed container must be capable of being tightly re- closed after use. Where a tightly-closed container is specified, a hermetically sealed container may be used for a single dose of an article. A gas cylinder may be considered to be a metallic, tightly-closed container designed to hold gas under pressure.

Well-closed container. A well-closed container protects the contents from extraneous solids and liquids and from loss of the article under normal conditions of handling, shipment, storage and distribution. ( IP-2007)

3. CONTAINERS FOR PHARMACEUTICAL PRODUCTS

This is deals with the specific requirements, guidance and information on containers used for packaging pharmaceutical products. The materials that are used in the manufacture of containers, particularly plastic containers, the raw materials and additives used and the formulations employed should be agreed with the users of the containers. Any changes should also be notified to the users from time to time to enable them to ensure the stability and safety of the drugs packed in the containers. ( IP-96-2007)

4. GLASS CONTAINERS

Glass has been used for over 6000 years, dating to incient times. Though the years and with more knowledge of its technology, glass has become the most widely used drug packaging material. (Willy Sindey H.)

Glass, originally the most widely used drug packaging material, is still favored for many drug packages because of its transparerancy, its excellent resistance to attack by most liquids and its total impermeability to glass. (Wilmer A. Jenkinns)

Glass containers may be colourless or coloured. Neutral glass is a borosilicate glass containing amounts of boric oxide, aluminum oxide, alkali and/or alkaline earth oxides. It has a high hydrolytic resistance and a high thermal shock resistance.

Soda-lime-silica glass is a silica glass containing alkali metal oxides, mainly sodium oxide and alkaline earth oxides, mainly calcium oxide. It has only a moderate hydrolytic resistance.

According to their hydrolytic resistance, glass containers are classified as:

Type I-Borosilicate Glass. In this highly resistant glass, a substantial part of the alkali and earth cation are replaced by boron and/or aluminum and zinc. Glass containers which are of neutral glass, with a high hydrolytic resistance, suitable for most preparations whether or not for parenteral use,

Type II- Regular Soda-Lime Glass. Glass containers which are usually of soda-lime- silica glass with high hydrolytic resistance resulting from suitable treatment of the surface. They are suitable for most acidic and neutral, aqueous preparations whether or not for parenteral use.

Type III-N-General-purpose Soda-Lime Glass. Glass containers which are usually of soda- lime-silica glass with only moderate hydrolytic. (IP-96, IP-2007, Leon Lachman)

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

4.1. Problems Associated With Glass Containers

Sorption

When formulation components are removed by a package two different processes are involved: adsorption onto the surface and absorption into the package wall by diffusion. A component may also desorbs from the outer surface of the package and pass into the atmosphere if it is volatile enough. Strong adsorption or absorption requires a strong chemical interaction between the component and the packaging material in addition, for a high level of absorption the packaging material must be permeable to the component. Glass has a chemically active surface but is an absolute barrier so that while adsorption can be strong, no absorption occurs.

4.2. Glass Containers for Injectable Preparations

Glass containers intended for injectable preparations may be ampoules, vials or bottles. The glass used in the manufacture of such containers complies with one of the requirements for hydrolytic resistance given below. There are three types of glass that are suitable for use. The types are distinguished by the resistance to water attack of new (not previously used) glass containers, the degree of attack being determined by the amount of alkali released from the glass under the conditions specified.

Type I glass (commonly known as neutral glass) offers a high hydrolytic resistance due to chemical composition of the glass. Type II glass has a high hydrolytic resistance due to an appropriate surface treatment. Both types of glass may be used for different types of injectable preparations depending on their physico-chemical properties. Type III glass offers only a moderate hydrolytic resistance and should be used only for non-aqueous liquid preparations or for powders for injection or for injectable preparation where adequate suitability tests have indicated that this type of glass is satisfactory or for preparations not for parenteral use.

Containers of Type II or Type III glass should be used once only. Glass containers with a hydrolytic resistance higher than that prescribed for the preparations to be contained may always be used.

Containers for injectable preparations are made from uncoloured glass except that coloured glass may be used for substances known to be light - sensitive; in such cases, the containers should be sufficiently transparent to permit visual inspection of the contents.(IP-96-2007)

Testing of Glass Containers

Hydrolytic resistance

Carry out the determination on the unused containers. The number of containers to be examined and the volumes of test solution to be used are given in Table 1. Rinse each container at least twice with water at room temperature. Just before the test rinse each container with freshly prepared distilled water. Fill the containers to the brim with freshly prepared distilled water, empty them and determine the average overflow volume.(IP-96-2007)

TABLE-1 (IP-96)

|

Nominal capacity of container (ml) |

Number of containers to be used |

Volume of test solution to be used for titration (ml) |

|

5 or less |

at least 10 |

50.0 |

|

6 to 30 |

at least 5 |

50.0 |

|

More than 30 |

at least 3 |

100.0 |

Fill the ampoules with freshly prepared distilled water to the maximum volume compatible with sealing them by fusion of the glass and seal them. Fills bottles or vials to 90% of their calculated overflow volume and cover them with borosilicate glass dishes or aluminium foil previously rinsed with freshly prepared distilled water. Place the containers in an autoclave containing water so that they remain clear of the water. Close the autoclave, displace the air by passage of steam for 10 minutes, raise the temperature from 100° to 121° over 20 minutes, maintain a temperature of 121° for 60 minutes and reduce the temperature from 121° to 100° over 40 minutes, venting to prevent vacuum. Remove the containers from the autoclave and cool them in a bath of running tap water. Carry out the following titration within 1 hour of removing the containers from the autoclave. Combine the liquids from the containers being examined, measure the volume of test solution specified in Table 1 into a conical flask and add 0.15 ml of methyl red solution for each 50 ml of liquid. Titrate with 0.01M hydrochloric acid taking as the end-point the colour obtained by repeating the operation using the same volume of freshly prepared distilled water. The difference between the preparations represents the volume of 0.01M hydrochloric acid required by the test solution. Calculate the volume of 0.01M hydrochloric acid required for each 100 ml of test solution, if necessary. The result is not greater than the value stated in Table 2.

TABLE-2 (IP-96)

|

Capacity of container [corresponding to 90% average overflow volume (ml)] |

Volume of 0.01M hydrochloric acid per 100 ml of test solution |

|

|

|

Type I or II glass (ml) |

Type III glass (ml) |

|

Not more than 1 |

2.0 |

20.0 |

|

More than 1 but not more than 2 |

1.8 |

17.6 |

|

More than 2 but not more than 5 |

1.3 |

13.2 |

|

More than 5 but not more than 10 |

1.0 |

10.2 |

|

More than 10 but not more than 20 |

0.80 |

8.1 |

|

More than 20 but not more than 50 |

0.60 |

6.1 |

|

More than 50 but not more than 100 |

0.50 |

4.8 |

|

More than 100 but not more than 200 |

0.40 |

3.8 |

|

More than 200 but not more than 500 |

0.30 |

2.9 |

|

More than 500 |

0.20 |

2.2 |

Distinction between Types I and II glass: Examine the number of containers indicated in table 1. Rinse the containers twice with water and then fill completely with a 4% v/v solution hydrofluoric acid and allow to stand at room temperature for 10 minutes. Empty the containers and rinse carefully five times with water. Carry out the procedure described under Hydrolytic resistance. Compare the results with the limiting values given in Table 2. For Type I glass the values obtained with the hydrofluoric acid-treated containers are closely similar to those stated in the Table for Type I or Type II glass. For Type II glass the values obtained with the hydrofluoric acid-treated containers greatly exceed those given in the Table for Type I or Type II glass and are similar to those given for Type III glass.

Arsenic: Glass ampoules should comply with the following test. Carry out the test on ampoules the inner and outer surfaces of which are washed five times with freshly distilled water.

Prepare a test solution as described in the test for Hydrolytic resistance for an adequate number of ampoules to produce 50 ml. Pipette 10 ml of the test solution from the combined contents of all the ampoules into a flask, add 10 ml of nitric acid and evaporate to dryness on a water-bath. Dry the residue in an oven at 130° for 30 minutes. Cool, add to the residue 10.0 ml of hydrazine-molybdate reagent, swirl to dissolve and heat under reflux on a water bath for 20 minutes. Cool to room temperature. Determine the absorbance of the resulting solution at the maximum at about 840 nm, Appendix 5.5, using 10.0 ml of hydrazine-molybdate reagent as the blank. The absorbance of the test solution does not exceed the absorbance obtained by repeating the determination using 0.1 ml of arsenic standard solution (10ppm As) in place of the test solution (0.1ppm).(IP-96-2007)

5. PLASTIC CONTAINERS

Plastic containers for pharmaceutical products are made from plastics based on the following polymers: polyethylene (low or high density), polypropylene, polyvinyl chloride, polystyrene and to a lesser extent polyethylene terephthalate. The containers consist of one or more polymers together with certain additives if necessary. They should be manufactured from materials that do not include in their composition any substances that can be extracted by any contents in such quantities so as to alter the efficacy or stability of the product or to present a toxic hazard.

Additives may consist of antioxidants, lubricants, plasticisers and impact modifiers but not antistatic agents and mould-release agents.

The selection of a suitable plastic container should be based on a knowledge, obtained from the supplier of the raw materials used and of the composition of the plastic so that potential hazards can be assessed.(IP-96)

Before examination of various type plastics and form that are used in packaging pharmaceuticals. It is useful to consider some of the more important characteristics which have led to wide use of plastic generally. (James Swarbrick)

The plastic container chosen for any particular product should be such that the ingredients of the product in contact with the plastic material are not significantly adsorbed on its surface and do not significantly migrate into or through the plastic. Type samples of the intended container should be packed with the product and tested under conditions that reproduce those that would be encountered in use. These tests should include examination of the product to ensure absence of any sensory, chemical or physical change, an assessment of changes in the quantity of contents due to permeability of the plastic, detection of changes in pH, an assessment of the effects of light, chemical tests and where necessary, biological tests. Containers from bulk production should conform to the type sample in every respect. It should be ensured that there is no change in the composition or any change in the manufacturing method used by the manufacturer and more importantly, that no use is made of scrap material. It must be emphasized that changes in the composition of the plastic, reworking or inadequate control of processing can bring about changes which may invalidate the results of type testing. Samples from production should be tested to ensure conformance to type samples and test schedules should be designed to check departures from the characteristic of the type sample.(IP-96)

Plastics may be defined as any group of substances, natural or synthetic origins, consisting chiefly polymer of highly moleculer weight, that can be modulated into a shape or form by heat and pressure.(D.A.DEAN)

The biological and chemical tests described below are intended for plastic containers in which pharmaceutical preparations are dispensed. It should be appreciated that these tests by themselves are not sufficient to establish safety or suitability of the plastic containers for the preparations and it is necessary to consider the results of the tests in conjunction with the information given above. Specification should be agreed with the container manufacturer and should be revised if the composition of the plastic or the ingredient quality is altered or the processing treatment is changed.(IP-96)

Materials used for plastics

1. Polyesters:

Thin PET films have high physical strength, excellent optical properties and very good thermal stabilities. PET film can withstand all the major methods of sterilization. One point of caution – the use PVC coated polyester should be avoided in HCP. Polyester film must be combined with heat seal coating. Heavier gauge semi-rigid unoriented polyester film is used in blister pack.

2. Nylon(polyamides)

Although nylon is available in a range of thickness and has a wide usage in form/film/seal food packaging application it is hardly suited to HCP. It has good strength characteristics and excellent transparency but it is likely to degraded when expose to radiation sterilization. Nylon films are also sensitive to heat and moisture and wrinkle badly during steam sterilization.

3. PVC(polyvinyl chloride)

This film is widely used in food packaging. It has almost glass like clarity and is reasonably priced. In HCP however it is severe limitation owing to its performance in sterilization. It should be never used with radiation sterilization because it turns red brown when expose to gamma rays.

4. Polystyrene

Although inexpensive polystyrene has very limited used in HCP. It lakes impacts strength and impact modified grades have poor optical properties.

5. Polyethylene (LDPE and HDPE)

LDPE with lower melting point than HDPE is easier to heat seal, but HDPE has better moisture barrier properties and better tensile strength. Modified by edition of small quantities of co-monomer (e.g. 3-5% of ethylene vinyl acetate [EVA] ) the performance of PE is enhanced apperecibly in respect of sealing characteristics and adhesion to several substracts. In HCP polyethylene and co-polymer are normally used as primary packaging films (eg. Vent bags), but there used to provide heat seal properties to laminates is more important. It is not advisable to used LDPE for steam sterilization because of its low melting point, but some grades of HDPE has been successfully used.

6. Polypropylene (PP)

This plastics is available (homo and co-polymers) as cast and blown films with and without orientation. In HCP the non-oriented cast co-polymer is of most interest. The sensitivity of PP to radiation has already been mentioned. PE at lower price is adequate for ETO sterilization. Thus PP is sealent of limited interest used primarily where steam sterilization is involved. (H. Lockhart)

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

5.1. Problems Associated With Plastic Containers

Sorption

When formulation components are removed by a package two different processes are involved: adsorption onto the surface and absorption into the package wall by diffusion. A component may also desorbs from the outer surface of the package and pass into the atmosphere if it is volatile enough. Strong adsorption or absorption requires a strong chemical interaction between the component and the packaging material in addition, for a high level of absorption the packaging material must be permeable to the component. For plastics, on the other hand, both adsorption and absorption are possible. In the literature, when adsorption and absorption occur together, there is rarely a distinction made between the two and therefore the term sorption will be used to indicate both are taking place.

Leaching

Leaching is primarily a problem with IV fluids and large volume parentrals. Widely studied examples are the leaching of plasticizers from PVC IV bags, extraction of additives from rubber closures and corrosion of glass surfaces. Most leaching problems occur with plastics because of the presence of additives such as fillers, activators and plasticizers. Leaching can cause discoloration, precipitation, change in pH, and contamination that can lead to increased toxicity or instability of the drug.

Permeation

The transmission of gases, vapors, or liquids through plastic packaging materials can have an adverse effect on the shelf-life of a drug. Permeation of water vapor and oxygen through the plastic wall into the drug can present a problem if the dosage form is sensitive to hydrolysis and oxidation. Temperature and humidity are important factors influencing the permeability of oxygen and water through plastic. An increase in temperature reflects an increase in the permeability of the gas.

Chemical reactions

· An oxidative reaction accelerated by the presence of low levels of copper.

· Contamination arising from the extraction of plasticizers from PVC pipelines.

· A bulk product involving clarity of solution test was packed in a low-density polytethylene bag inside a metal drum. On reaching its destination the product failed the clarity of solution test. This was traced to a lubricant in the polyethylene which achieved its effect by being present at the surface of the film. During transportation the lubricant was physically removed from the film surface, by vibration with the solid product.(Gilbert S. Banker)

5.2. Plastic Containers for Non-injectable Preparations

Leakage test: Fill ten containers with water, fit with the intended closures and keep them inverted at room temperature for 24 hours. There are no signs of leakage from any container.

Collapsibility test: This test is applicable to containers which are to be squeezed in order to remove the contents. A container, by collapsing inward during use, yields at least 90% of its nominal contents at the required rate of flow at ambient temperature.

The following tests are applicable to containers intended for filling oral liquids.

Clarity of aqueous extract: Select unlabelled, unmarked and non-laminated portions from suitable containers, taken at random, sufficient to yield a total area of sample required, taking into account the surface area of both sides. Cut these portions into strips, none of which has a total area of more than 20 cm2. Wash the strips free from extraneous matter by shaking them with at least two separate portions of distilled water for about 30 seconds in each case, then draining off the water thoroughly.

Select cut and washed portions of the sample with a total surface area of 1250 cm2, transfer to a flask, previously cleaned with chromic acid mixture and rinsed with several portions of distilled water and add 250 ml of distilled water. Cover the flask with a beaker and autoclave at 121° for 30 minutes. Carry out a blank determination using 250 ml of distilled water. Cool and examine the extract; it is colourless and free from turbidity.

Non-volatile residue: Evaporate 100 ml of the extract obtained in the test for Clarity of aqueous extract to dryness and dry to constant weight at 105°. The residue weighs not more than 12.5 mg.(IP-96)

5.3. Plastic Containers for Injectable Preparations

General Requirements

Material: Only virgin plastic material, which is practically odourless, is used in the manufacture of containers. Additives such as antioxidants, lubricants, plasticisers, stabilisers etc… may be used but no pigment may be used for purposes of colouring.

Characteristics: The container is sufficiently transparent to allow adequate visual inspection of its contents. A filled container is to be sterilisable by heat or any other method without showing signs of shrinkage, distortion, discolouration, loss of transparency, cracking, tackiness or any other kind of deterioration.

The container is of a size, shape and design (including provisions for attachments where necessary) suitable for its intended use.

5.4.. Plastic Containers for Opthalmic Preparation

Plastic containers for optahalmic preparations are made from plastic composed of a mixture of homologous compounds having a range of molecular weights. Such plastics frequently contain other substances such as residues from the polymerization process, plasticisers, stabilizers, antioxidants, lubricants and pigments. For deciding the suitability of a plastic for use as a container for opthalmic preparations, factors such as the composition of the plastic, processing and cleaning procedures, contacting media, adhesives, adsorption and permeability of preservatives, conditions of storage, etc. Plastics containers for opthalmic preparations comply with the following tests.

Leakage test, Collapsibility test; Clarity of aqueous extract; Non-volatile residue: Comply with the tests described under Plastic containers for Non-injectable Preparations.

Systemic injection test; Intracutaneous test: Comply with the tests described under plastic containers for Injectable Preparations.

6. Tests on Plastic Containers

Leakage test, Collapsibility test: Comply with the tests described under Plastic Containers for Non-injectable Preparations.

Transparency: Prepare a 16-fold dilution of the suspension prepared for the standard suspension, Appendix 6.1, so as to give an absorbance at about 640 nm of 0.37 to 0.43, Appendix 5.5

Fill five empty containers to their nominal capacity with the diluted suspension. The cloudiness of the diluted suspension in each container is detectable when viewed through the containers, as compared with a container of the same type filled with water.

Water vapour permeability: Fill five containers with the nominal volume of water and heat-seal the bottles with an aluminum foil-polyethylene laminate or other suitable seal. Weigh accurately each container and allow to stand (without any overwrap) for 14 days at a relative humidity of 60 ± 5% and a temperature between 20° and 25°. Reweigh the containers. The loss in weight in each container is not more than 0.2%.

Containers of plasticised polyvinyl chloride (PVC) for Injectable Preparations (Intravenous Infusions) comply with the following additional test.

Extractable di (2-ethylhexyl) phthalate: Not more than 0.010% w/v, determined by the following method. Using the donor tubing and the needle or adaptor, fill the empty container with a volume equivalent to half the nominal capacity with an extraction solvent consisting of ethanol diluted to have a relative density, Appendix 8.15, of 0.9373 to 0.9378 and previously heated to 37° in a well-stoppered flask. Remove the air completely from the container and seal the donor tube. Immerse the filled container in a horizontal position in a water-bath maintained at 36° to 38° for 60 ± 1 minutes without shaking. Remove the container from the water-bath, invert it gently 10 times and transfer the contents to a glass flask. Immediately measure the absorbance at the maximum at about 272 nm, Appendix 5.5. Calculate the percentage of di(2-ethylhexyl)phthalate from a calibration curve obtained from the absorbances of standard solutions of di(2-ethylhexyl)phthalate in the same extraction solvent.

7. Tests on Plastic Container Material

The following tests are done on portions of the container that are unlabelled, unprinted or non-laminated or on the granules of plastic in the case of containers made by the ‘form-fill-seal’ process.

Barium: Moisten 2 g with hydrochloric acid and ignite in a platinum dish. Dissolve the residue in 10 ml of 1M hydrochloric acid, filter and add 1 ml of 1M sulphuric acid to the filtrate. Any turbidity produced is not greater than that produced on adding 1 ml of 1M sulphuric acid to a mixture of 10 ml barium standard solution (10ppm Ba) and 10 ml of 1M hydrochloric acid.

Heavy metals: To 2.5 g in a long-necked round-bottomed flask add 20 ml of sulphuric acid and char for about 10 minutes. Add hydrogen peroxide solution (100 vol) dropwise to the hot solution until it becomes colourless, heating between each addition until white fumes are evolved. Cool, transfer to a platinum dish with the aid of 10 ml of water and evaporate to dryness. Dissolve the residue in 10 ml of 1M hydrochloric acid, filter if necessary and add sufficient water to produce 25 ml (solution A).

To a mixture of 10 ml of solution A and 2 ml of acetate buffer pH 3.5 add 1.2 ml of thioacetamide reagent, mix immediately and allow to stand for 2 minutes. Any yellow colour in the solution is not more intense than the yellow colour obtained by repeating the operation using 10 ml of cadmium standard solution (10ppm Cd) in place of solution A. Any brown colour in the solution is not more intense than that obtained by repeating the operation using a mixture of 5 ml of lead standard solution (10ppm Pb) and 5 ml of water in place of solution A.

Tin: To 10 ml of solution A obtained in the test for Heavy metals add 5 ml of sulphuric acid (20%), 1 ml of a 1% w/v solution of sodium dodecyl sulphate and 1 ml of zinc dithiol reagent. Heat in a water-bath for exactly 1 minute, cool and allow to stand for 30 minutes. Any red colour in the solution is not more intense than the red colour obtained by repeating the operation using 10 ml of tin standard solution (5 ppm Sn) in place of solution A.

Zinc: To 1 ml of solution A obtained in the test for Heavy metals add sufficient water to produce 100 ml . To 10 ml of the resulting solution (test solution) add 5 ml of acetate buffer solution pH 4.4, 1 ml of 0.1M Sodium thiosulphate and 5 ml of 0.001% w/v solution of dithizone in chloroform, shake and allow to stand for 2 minutes. Any violet colour in the chloroform layer is not more intense than that obtained by repeating the operation using a mixture of 2 ml of zinc standard solution (10 ppm Zn) and 8 ml of water in place of the test solution. Carry out a blank determination using 10 ml of water in place of test solution. The test is not valid unless the chloroform layer obtained in the blank determination is colourless.

Residue on Ignition: Not more than 0.1%, determination on 5 g of the sub-divided sample in a suitable tared crucible. Ignite to constant weight in a muffle furnace at 800º + 25º. Allow the crucible to cool in a disiccator after each ignition.(IP-96)

9. METAL CONTAINERS

Materials used for various pharmaceutical drug-delivery system include tin-plated steel, mild-steel, stainless-steel, tin-free steel, and aluminium and its various alloys. Metals is strong, opaque, and impermeable to light, odour, bactaria etc. It is resistant to high and low temperatures. Malleable and ductile, metal is usually used in thin section.

Metal used for various pharmaceuticals drug delivery system include tin-plate, mild-plate, stainless steel, tin-free steel, aluminum and various alloys. (Banker Gilbert)

9.1. Metal Containers for Eye Ointments

Metal collapsible tubes comply with the following test for metal particles. Select a sample of 50 tubes from the lot to be tested and clean each tube by vibration and/or "blowing". (A lot may be either the tube manufacturer’s day’s production or a consignment delivered to the tube user). Fill the tubes with a suitable molten eye ointment base, close the open end of each tube by a double fold and allow the filled tubes to cool overnight at a temperature of 15° to 20°.

Assemble a metal bacteriological filter with a 4.25-cm filter paper of suitable porosity supported on suitable perforated plate in place of the standard sintered carbon disc and heat it in a suitable manner to a temperature above the melting range of the base. Remove the caps from the cooled tubes and apply uniform pressure to the closed end of each tube in turn, in such a manner that the time taken to express as much of the base as possible through each nozzle is not less than 20 seconds. Collect the extruded base from the 50 tubes in the heated filter, applying suction to the stem of the filter in order to draw the molten base through the filter paper. When all the melted base has been removed, wash the walls of the filter and the filter paper with three successive quantities, each of 30ml, of chloroform, allow the filter paper to dry and immediately mount it between glass for examination.

Examine the filter paper under oblique lighting with the aid of magnifying glass with a graticule of 1 mm squares, one of which is sub-divided into 0.2 mm squares and note (a) the number of all metal particles 1 mm in length and longer, (b) the number in the range 0.5 mm to less than 1 mm and (c) the number in the range 0.2 mm to less than 0.5 mm.

Carry out two further examinations with the filter paper in two different positions so that the lighting comes from different directions and calculate the average number of metal particles counted in each of the three ranges specified. Give each metal particle detected on the filter paper a score as follows and add the scores together.(IP-96)

TABEL-7(IP-96)

|

Particles 1 mm and above |

50 |

|

Particles 0.5 mm but less than 1 mm |

10 |

|

Particles 0.2 mm but less than 0.5 mm |

2 |

|

Particles less than 0.2 mm |

Nil |

The lot of tubes passes the test if the total score is less than 100 points; if the total score is more than 150 points, the lot fails the test. If the total score is between 100 and 150 (inclusive), the test is repeated on a further sample of 50 tubes and the lot passes the test if the sum of total scores in the two tests is less than 150 points.

NOW YOU CAN ALSO PUBLISH YOUR ARTICLE ONLINE.

SUBMIT YOUR ARTICLE/PROJECT AT articles@pharmatutor.org

Subscribe to Pharmatutor Alerts by Email

FIND OUT MORE ARTICLES AT OUR DATABASE

10. CLOSURES

10.1. Inroduction

Closuresare devices and techniques used to close or seal a bottle, jug, jar, tube, can, etc. Closures can be a cap, cover, lid, plug, etc.

All packages must be closed to protect and contain the content. Closure is accomplished in one of three ways: sealing of the container with adhesives, sealin the containers with heat, or or by use of separate devices. (Wilmer A. Jenkinns)

10.2. History

Early pottery and ceramic containers often had lids that fit reasonably snug onto the body of the container. The narrow necks of ancient amphora were closed with a plug of cork, wood, or ceramic and sealed with mortar.[3]Wooden Barrels often had bungholes closed by cork or wood bungs. Some early tinplate cans were made with threaded necks for screw top closures.Beverage bottles started using the Hutter Stopper in 1893. This involved a porcelainplug fitted with a rubber washer, which was then forced down into the lip of the bottle. This technique only works with carbonated beverages. The Hutter Stopper became standard in beer bottling in the late 1890s / early 1900s. Bail closures on bottles were invented by Henry William Putnam in 1859. (www.encyclopedia.com)

A variety of problems can occur involving container closurs:

An over-the-counter (OTC) product with a high sugar content suffered, when it use from crystallization of sugar arrond the neck of sugar (James Swabrick)

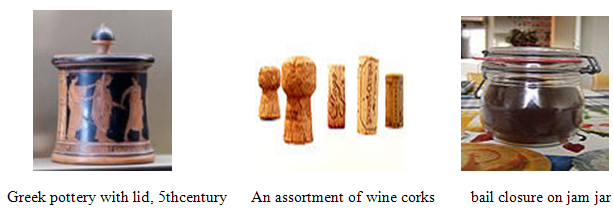

Greek pottery with lid, 5thcentury An assortment of wine corks bail closure on jam jar

The world's first modern bottle cap, the crown cork, was invented by William Painter in 1890 in Baltimore. The screw cap using rust resistant aluminum was first used in prescription drug bottling in the 1920s.Molded urea based bottle caps were first introduced in the early 1900s.

A history of accidents involving children opening household packaging and ingesting the contents led the US Congress to pass the Poison Prevention Packaging Act of 1970.

10.3. Purpose of closures

Many containers and packages require a means of closing. It can be a separate device or seal or sometimes a integral latch or lock. Depending on the contents and container, closures have several functions:

- Keep the container closed and the contents contained for the specified shelf life until time of opening

- Provide a barrier to dirt, oxygen, moisture, etc. Control of permeationis critical to many types of products: foods, chemicals, etc.

- Keep the product secure from undesired premature opening

- Provide a means of reclosing or reusing the container

- Assist in dispensing and use of product

- Allow reasonable ease to open the container by the intended user. Difficult to open containers may cause wrap rage. The forceor torque required to open a closure is an important consideration for packaging engineers.

Many types of packaging with their closures are regulated for strength, safety, security, communication, recycling, and environmental requirements.

10.4. Types of closures

Closures need a means of attaching to the container with sufficient security. Threads, lugs, hinges, locks, adhesives, etc. are used.

Many closures need to have the ability to adjust to slight manufacturing variation in the container and the closure structure. Some closures are made of flexible material such as cork, rubber, or plastic foam. Often an o-ring or a closure liner (gasketmade of pulp or foam cap liner) is used. Linerless closures often use a deformable plastic rim or structure to maintain the seal.Secondary seals are common with sensitive products that may deteriorate or where extra security is needed. Foil or plastic innerseals are used on some bottles, Heat sealed lidding films are used on some tubs. External shrink bands, labels, and tapes are sometimes used outside the primary closure structure.

Screw top, Threaded or Lug

A screw closure is a mechanical device which is screwed on and off of a threaded "finish" on a container. Either continuous threads (C-T) or lugs are used. Metal caps can be either preformed or in some instances, rolled on after application. Plastic caps may use several types of molded polymer.

Some screw tops have multiple pieces. For example, a mason jar often has a lid with a built in rubbery seal and a separate threaded ring or band.

Crown caps or Crimp-on

Beverage bottles are frequently closed with crown beverage caps. These are shallow metal caps that are crimped into locking position around the head of the bottle.

Crown cap

Snap on or Press-on

Some closures snap on . For opening , the top is designed to pry off or , break off, or have a built in dispenser.

Friction fit

Some containers have a loose lid for a closure. Laboratory glassware often has ground glass joints that allow the pieces to it find be fitted together easily.

An Interference fit or friction fit requires some force to close and open, providing additional security. Paint cans often have a friction fit plug.

Roll-on Closures

The aluminum roll-on cap can be sealed securely, opened